If messing with diodes, rectifiers and the like is gobbledygook I'd go with a rheostat as suggested earlier = see posts in the linked threads by ADCX Rob. That would be a simple 2 terminal connection, no soldering, etc. The Lionel rheostats go for around $10-20 on eBay and there are dozens for sale right now.

As for the triggering, I agree with you that insulating pin(s) alone will not work.

I'm not so presumptuous to say what's in your comfort zone and budget. That said, based on your comments so far, I'd suggest something like this:

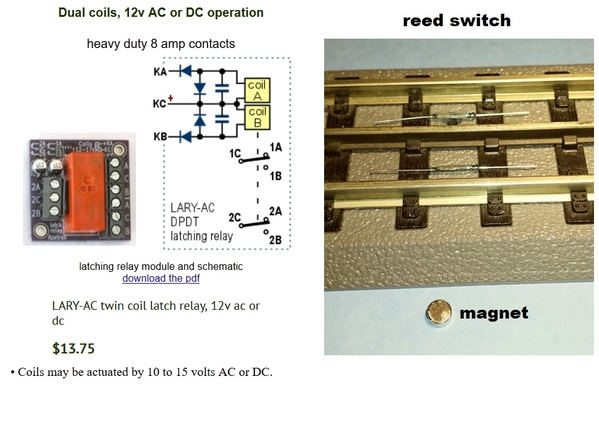

Suppose you have a so-called 2-input (a.k.a dual-coil) latching relay. You trigger the "set" input of a latching relay and it closes its electrical contact. The relay stays closed until it receives a trigger on the "reset" input. So the basic idea to to set the latching relay when the train is about to enter the downgrade...and then reset the latching relay when the train exits the downgrade. Latching relays as a component are just a couple bucks...but assembled with screw-terminals to eliminate soldering and such run maybe $10 or more. Example above is from Azatrax which carries a broad line of interesting and useful electrical doo-dads for model train applications.

The latching relay could be "set" and "reset" by a 10-cent magnet passing over a 50-cent reed switch. I just made up the costs as I have lifetime supplies of these but it's one of those cases of you'll pay more for shipping! There are pre-wired reed switches as these are very common in alarm systems to detect an open window or door.

As shown in the picture, you can embed the reed switch on one side of the track. You can place the magnet on one side of the engine (or caboose or last car in consist). By "one side" that means between the center-rail and either the left outer rail or the right outer rail. You have to think about it for a moment, but that means if the consist is going the "other" direction, the magnet will not pass over the reed switch and the latching relay is never set/reset.

Note that I suggest this method as you apparently have only a few engines that would have to be out-fitted with the magnet.

Then, when the relay is set the reduced rheostat voltage would be swapped into the track center rail. And when the relay is reset, the original "full" voltage would be restored to the track center rail. If you are only operating 1 engine at a time, this full or reduced voltage could be applied to the entire loop and you would not need to fabricate isolated "blocks" with insulated pins and center-rail "islands".

Anyway, I see how this idea too is not simple plug-and-play. But in the absence of other suggestions, if this is indeed something you'd like to pursue... or just discuss further in the spirit of a forum... I can elaborate. ![]()