Yes, new wheels, pantograph, flag posts, bulbs and screws to mount the motor frame to the chassis (replacing the toothpicks that were used previously). All wiring outside the motor itself was replaced. All brass and steel parts were cleaned in an ultrasonic cleaner (from my clock cleaning days) then gently scrubbed, rinsed and dried.

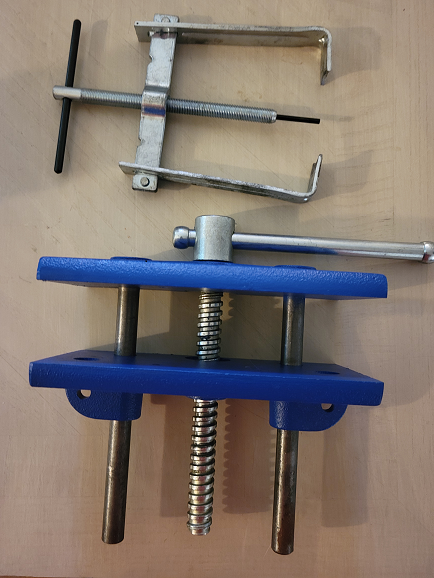

@Strummer: A few years ago I asked for advice on this forum on how to replace the wheels on a Lionel 252 I was working on. The tools below were recommended and have worked like a charm for me since. I used a faucet puller to carefully pull the old wheels off. Then the woodworkers vice to put the new wheels onto the cleaned axles. I put the drive wheels onto the axles first in the vise one at a time. Then I put the axles through the frame and put the other wheels on. This allows the gear teeth to mesh without being forced. That's been my method but I defer to others with more experience to describe other processes.