I use R/C aircraft servos for under the table switch machines but this will be the same for the DZ's . If you have a lot of them go to lowes get a 24 inch by 24 inch piece of sheet metal,and some #4 sheet metal screws .

Cut a rectangle with tin snips and bend a one inch flange on it and drill a 1/16 hole in the flanged part for your wire to stick up thru.

drill 2 holes on each side to mount it( If you have a drill press this goes very fast)

For wire I use 0.032 TIG welding wire it's stainless steel and stiff as heck

Try to center your switch machine in the hole in the table as best you can then I do this to both help with alignment and make the switch non- derailing

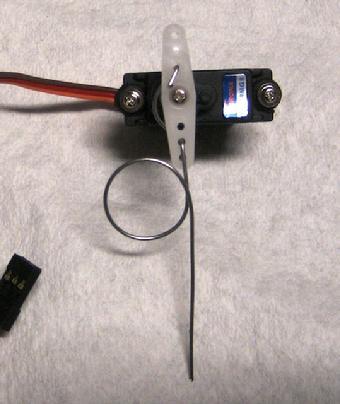

Drill a second hole in the switch machine arm. if your using 0.032 TIG wire a 3/32 bit will do it . now leaving about a half inch extra wrap the wire around a medium handle X-Acto knife about 2 or 3 turns is fine this gives the switch rod a little spring.

Now bend a 90 on that half inch extra of wire and put it thru the first hole bend a "U" shape with needle nose and put it thru the second hole . the extra sticking out of the second hole gets bent against the switch arm this keeps your spring from turning

remember the switch points on any Ross switch only move about a quarter of an inch.

The spring allows for a little give but and engine coming the other way can just drive thru the switch but don't worry there's plenty of pressure there to keep the wheels from picking the switch

This is one of my first switch motors I found it works better with a few more turns on the wire . That motor is smaller than a quarter.

If you make a template for your mount bracket it goes really fast and will be considerably cheaper than the Rix Rax mount

|

|