Update Nov 27th

The flat center roof section with side windows was difficult. I called a large train store that specialized in O-Scale brass to purchase the center roof section with 12 matching windows. The store said “That center roof section with windows is a single sheet of brass that’s included with the brass model kit. It’s not sold separately”. Umm… that puts a major setback on my plan.

Scrambling for a plan B. I drove to a local hobby store and purchased a 0.06” thick brass sheet for the center roof materiel and flat brass strips for dome sides and window frames. When I got home I worked on removing the extra knob off the top of the brass casting and then after hours of carefully studying all the parts. I realized I was in over my head and gave up.

There was no way I could figure out how to create 12 identical windows out of brass, with zero experience in this type material and my limited hand tools. And even if I could make perfect window openings how was I ever going to get the exact curvature of the domes outer window frames. After several failed attempts I gave up on making a homemade center dome section and contacted a professional with a CNC machine.

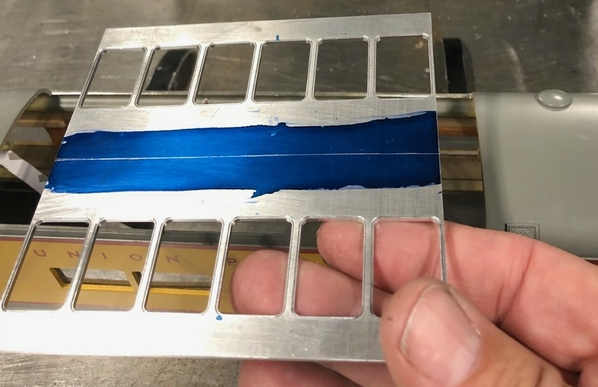

He calculated the window openings with a micrometer, identified the window corner radius and then created a CAD drawing on his PC. Then, he secured a sheet of 0.06” thick aluminum in the CNC machine, calculate the RPM needed based on the type of aluminum being cut and the size of the end mill (router cutting bit) being used. After inputting the data the automated CNC machine came to life and went to work cutting in 12 identical windows out the flat stock. As you can see below a complete center window section was created that’s the same exact thickness as the brass window assembly. The CNC machine even included the 0.01” thick frames around the windows.

Next we had to find a way to bend and form the sides of this new aluminum window assembly to match the brass window castings. For this, the CNC shop measured the internal radius of the brass casting.

He inputted the new data into the CNC machine and it went to work creating a solid aluminum mold that I could form the aluminum window sheet over. Send me an email if you want the contact information for this CNC shop.

Next, we centered the new 0.06” thick window section onto the mold and started forming it around and into the correct curved shape that would match the exact radius of the brass window castings.

Stay tuned for the next step…