I liked how my previous 18” Phoenix Railway aluminum passenger car turned out and decided to try a Budd style shell with fluted sides. This time I was going to try to recreate a 1950's era “Pacific” series sleeping car using a Phoenix shell. The names of these cars were not for specific places but were meant to give a pleasant feeling about the destination or terrain that was being traveled. For this build I picked the name Pacific Shore. Here’s a photo of the real Pacific Shore. http://www.rrpicturearchives.n...ture.aspx?id=4469054 .

In my opinion, these Phoenix Railways shells are a good alternative for different styles of 18” aluminum unpainted semi-scale passengers cars. After picking up a 1990’s era Phoenix shell with fluted sides from eBay I wrote down this building guide with step by step experiences for fellow O-gauge forum members.

Modifying and painting this Phoenix Railways aluminum shell

Passenger traffic was heavy after the war and Union Pacific ordered lots of new sleeping cars from Pullman Standard and American Car Foundry. But UP’s largest single series type sleeping car order after the war was for 50 sleeping cars in the 10 roomettes – 6 bedrooms arrangement from Budd. These new 10-6 Pacific series sleeping cars started being delivered on December 19th 1949 and Budd finished the order on June 29th 1950. The first 25 cars were painted Amour Yellow and Harbor Mist Gray to match the “City” fleets. The last 25 cars were painted in the Grayhound two-tone paint scheme to be used on conventional passenger trains. Then, in 1952 Union Pacific standardized colors and repainted all their passenger cars Amour Yellow, Harbor Mist Gray with red lettering and red stripes. Also, around 1955 all gray trucks used underneath Union Pacific’s streamline passenger cars were painted silver. The Union Pacific still runs the Pacific Domain (now called Willie James) in their heritage fleet. https://www.up.com/cs/groups/p...james_historical.pdf

To find detailed photos and information on these Pacific series sleeping cars I hunted down “The Streamliner” magazines Vol. 4, No. 4 and Vol. 5, No. 2 published by the Union Pacific Historical Society. In these issues Robert Darwin goes over construction details of these 50 Pacific series cars. At that time, all the other Union Pacific sleeping cars had smooth sides and only these Pacific series cars built by Budd had been fitted with fluted side panels. Once I had the detailed photos and information from the UPHS magazines I started working on my Phoenix Railways shell. In the photo below I'm test fitting the Phoenix shell on top of a K-Line frame with trucks and Lionel post war end caps.

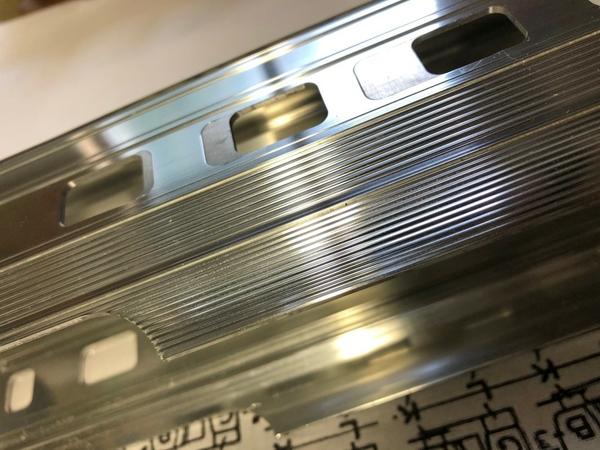

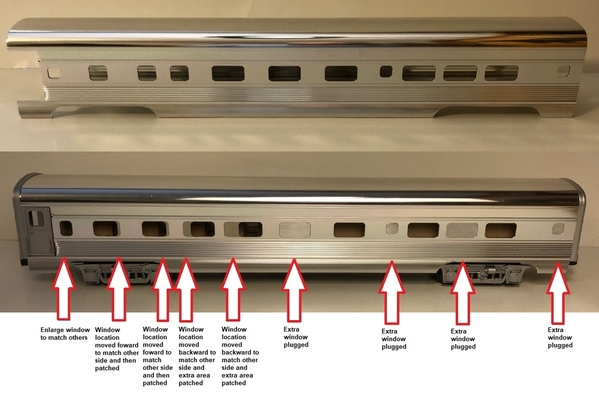

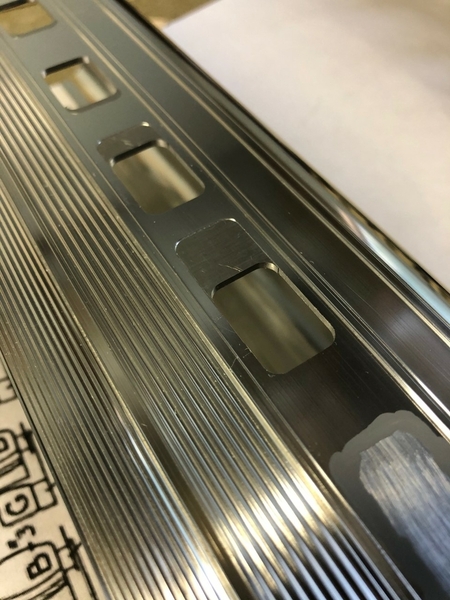

After the test fit I realized this shell needed its windows moved to better match a real Pacific series sleeping car. Phoenix Railways makes a great aluminum shell but the windows on the right hand side were nowhere near matching the original 1949 Budd plans. In my previous builds I would cut-in new windows by hand using a Dremel. And then fill-in unwanted openings using styrene. This time I contacted a professional with a CNC machine and had the new windows put into the shell at the correct locations. He measured the openings with a micrometer, identified the window corners as 7/64th radius and then created a CAD drawing on his PC. Next, he secured the aluminum Phoenix Railway shell in the CNC machine, calculate the RPM needed based on the type of aluminum being cut and the size of the end mill (router cutting bit) being used. After inputting all the data the automated CNC machine came to life and went to work cutting in new windows and moving over existing openings.

Next, the CNC machine was programmed to make small patches out of aluminum flat stock. These patches were needed so the right side window openings would be in the same correct locations as the roomette windows on the left side of the shell.

The quality of the new CNC aluminum patches was incredible. The accuracy was within 1000th of an inch. Far better than I could have done by hand. The Pacific Shore was turning out great and in the photo below you can see how the roomette windows were moved to the correct locations. Send me an email if you want the contact information for this CNC shop.

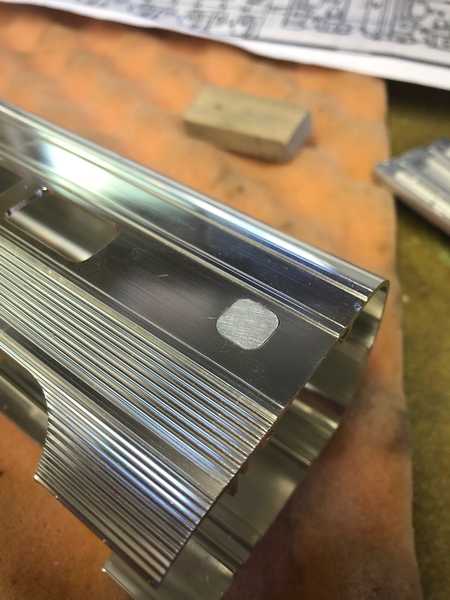

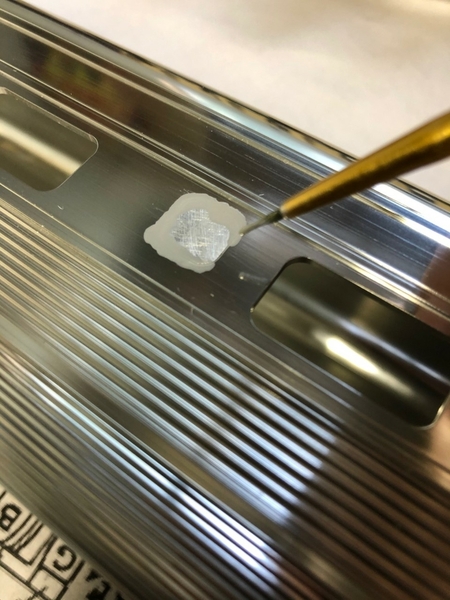

Next, the CNC shop had the machine make aluminum blanks to fill in the extra openings where there shouldn't have been windows on the right side of the Phoenix shell. When installing your new aluminum blanks into the shell it’s critical you do not glue the new plug too high up in the opening. If you do, you will not be able to easily sand them back down again. If needed clamp a small block of wood to the outside of the shell when pushing in your new aluminum blank from the inside. Use CA clue on the inside of the shell to secure new blanks in place.

Here is a look at 8 CNC’d window patches and blanks used on the right side of the shell. This new window arrangement is much closer to a real Pacific series sleeping car. Since I'm working with an 18” semi scale shell it did not have enough space to include all 10 roomettes in the front section of the car. This semi scale Phoenix Railway shell could only hold 4 roomettes on each side for a total of 8. Also, the small bathroom window next to the vestibule was enlarged by the CNC machine to be the correct height. Now the small bathroom window correctly matches the height of the other windows and the original Budd plans.

The only modification needed on the left side of the shell was adding a small window for the sleeping car attendant’s room.

Next gently wipe down the shell with 91% alcohol to remove any fingerprints/oil residue and prepare the surface for primer. Then, lightly go around your new aluminum patches and blanks with gray Tamiya primer on a small paint brush.

The gray primer easily fills and covers the seam between the blank and shell.

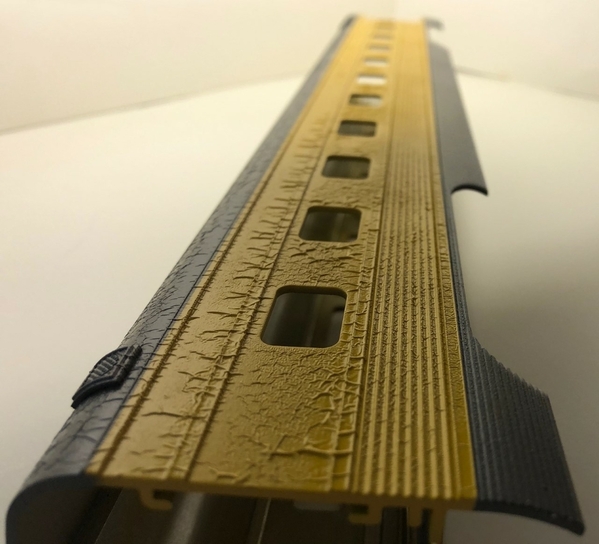

Once the primer has fully dried around the seams carefully sand the area smooth. Then, spray the whole shell with gray primer. In the photo below there used to be 7 windows... now there is only 3.

After applying primer look for any imperfections. If you find any, repeat the steps above until the area is perfectly smooth. The new CNC window patches and blanks blended in fantastic and I couldn’t tell where they were installed after the shell was sprayed with primer.

Next apply the correct Union Pacific colors for the year you are modeling. To make this sleeping car match the color online photos I used Scale-Coat II UP Amour Yellow #2085 and Scale Coat UP Harbor Mist Gray #2032. The first step was applying the Amour Yellow with an air brush. Wait 24-hours for the yellow paint to fully dry. Then tape-off the yellow areas and applied the Harbor Mist gray to the roof and skirts. Wait 24-hours for the roof and skirts to dry. Next, spray with Krylon gloss.

Fail.... apparently Krylon gloss is not compatible with Scale Coat II paint.

"Like" this post to show your support for the build and I will sand it down and try again.