I couldn't find the motor searching on the part number "Dayton CHM..." but found a similar Dayton gearmotor which retails for about $100 (yikes). Anyway, it's a sealed gearbox so ignore anyone who asks you to open that up to look for backlash or meshing issues!

0.45 RPM output is about ~3 degrees per second and it looks like about that speed in the video so I'm thinking the motor is working fine, there's enough voltage, etc.. As you point out, you can hear the gearmotor spinning when reversing direction several seconds before the TT moves. So I'm thinking the gearmotor output is 1:1 ratio or directly driving the TT platform.

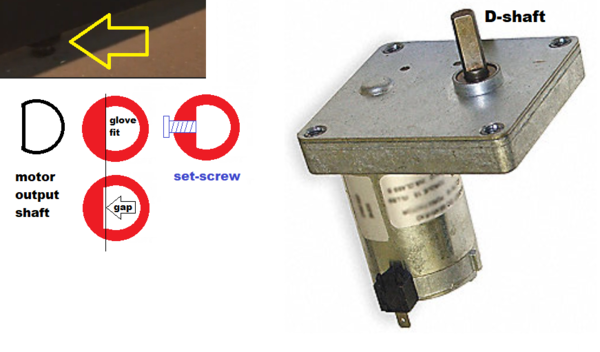

Does the TT "lift off" the motor "D" shaft? This would be at the, say, yellow arrow in photo above which I copied off your video. I assume when you said 1/2 shaft in your original post that this is what you meant. So let's say the D-shaft is as shown in black. Then there's a coupler/sleeve on the TT depicted in red. Obviously this needs to be a glove fit over the D shaft.

Let's say the sleeve is NOT an exact glove fit and there's a gap as shown in the lower red sleeve. This would exhibit the behavior shown in video. That is, there would be "play" in the TT of several degrees. When changing direction, the flat-face of the black D-shaft would have to rotate a few degrees to re-engage the flat-surface of the red sleeve. If stopping and restarting in the SAME direction, there would be no delay since the flat-face of the black D-shaft is already in contact with the flat-surface of the red sleeve.

A set-screw(s) depicted in blue can help to securely mate the two parts so there's no wiggle room.

That's my 2-cents.