I like GRJ's approach of using an MTH fan-driven smoke unit. 7/32" brass tubing turned out to be a useful...as did heat-shrink tubing for alignment and better air-leak sealing. Heat-shrink stays somewhat flexible for a minute or so after heating allowing alignment of the smoke-unit piping to the hole on the caboose roof to mate the chassis to the roof. Using flexible piping method allows the smoke unit to be placed away from the walls for heat management (melting plastic).

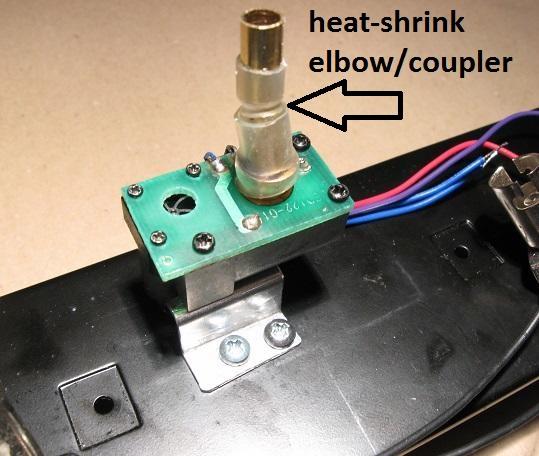

The arrow shows heat-shrink used as a coupler between two pieces of brass tube. In addition to making for easy bends, I figure this reduces conductive heat transfer from the smoke unit up to the roof.

In the measure-twice, cut-once department, I suggest thinking how to refill the smoke unit...ideally without having to open up caboose. Think if all fluid drops will make it into the chamber and not leak onto the chassis.

And here's version 1.0 in action on a RailKing caboose using GRJ's suggested power levels of 5V to the heater element (about 3 Watts) and 4.5V to the fan motor. I can't seem to get the video to embed so here's a youtube link: