I am designing an O gauge 3-rail layout to build in my retirement. My wife actually encouraged me to build what she named the “Train Mansion” in our backyard. My wife’s goal for my retirement is that she gives me my sack lunch and I go out the back door instead of the front door and I don’t return until supper time. The Train Mansion is 30’x40’ and is two floors. The layout will be in the lower floor. This is the Train Mansion. The upper floor was designed to look like a train station

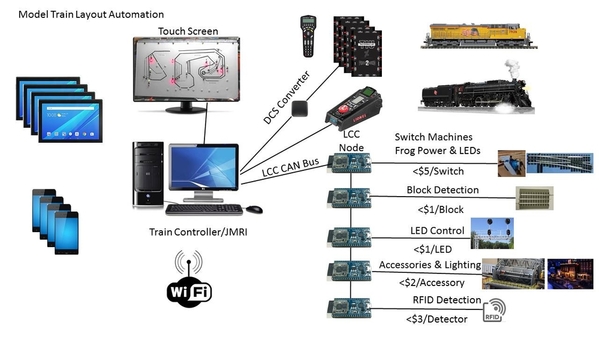

Using RRtrack I designed a Scaletrax layout for the lower floor. It is a very busy layout with over 100 turnouts. The real challenge came when I started to design the electronics for the layout. My wish list is: 1) Both DCS & Legacy, 2) Remote (Smart phone, tablet, DCS, & Legacy) & Computer Control, 3) Touch Screen Turnout and Accessory Control, 4) Block Detection, 5) Automated Block Signals and Accessories, 6) Under Layout Switch Machines and 7) RFID Detection. I read many OGR posts and learned a lot. The list of contributors that I learned from and admire is long. I also traded emails with Dave Hikel. What I learned is that my wish list was going to be very expensive and 8) Inexpensive Electronics needed to be added to my wish list. I started to play with the Arduino for automation and then moved on to the much more powerful ESP32. Links to ESP32 information https://en.wikipedia.org/wiki/ESP32 and https://www.espressif.com/site...p32_datasheet_en.pdf. I also started looking the layout automation that is going on in the HO world. Layout Command Control, LCC, is a new NMRA standard protocol for layout automation. This is a link to several presentations http://www.rr-cirkits.com/Clinics/Clinics.html. This is a link to NMRA LCC documentation https://openlcb.org. This is a link to a LCC discussion group https://groups.io/g/layoutcommandcontrol/topics. There are LCC automation products on the market that are using older technology than the ESP32. The 5 LCC nodes that I would like to develop: 1) 20 x LED controller and driver, 2) 20 x turnout control with a servo motor, LED control and frog power controller, 3) 24 x block detector, 5) 20 x accessory controller, 6) 6 x RFID controller. The controller hardware for the LED controller and turnout controller will be the same with different software. The electronics cost (assuming my time to assemble the nodes is free and the software is free) goal for the LED controller is less than $1/LED. The electronics cost goal for the turnout controller, servo, LED and frog controller is less than $4/turnout. The cost goal for the block detector is less than $1/block. The cost goal for the accessory controller is less than $2/accessory. The cost goal for the RFID reader is less than $3/reader. I think these are achievable goals. The current high level architecture of the electronics for my layout is shown in the drawing.

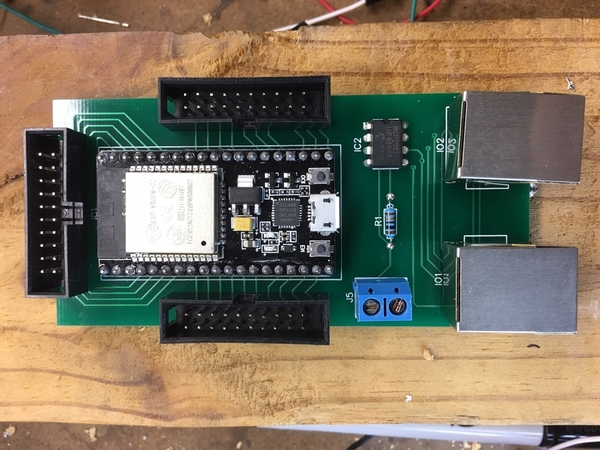

I would like the hardware designs and software to be open source. The nodes communicate with each other through the Controller Area Network, CAN, which is the bus used in automobiles. Ethernet cables are used for the wiring. I hope we can move from the cables to Wi-Fi in the future. I have an agreement with one of the developers of the LCC protocol that he will write the base CAN and LCC software if I build the ESP32 nodes for him. This is a picture of the first pass LED controller node hardware.

A growing user group is needed to make a new protocol and open source successful. I welcome help and hope this thread can be used to discuss and promote the LCC protocol. I will start a thread on each one of the LCC nodes. I still have 2-3 years to retirement so work commitments may slow down my posts.