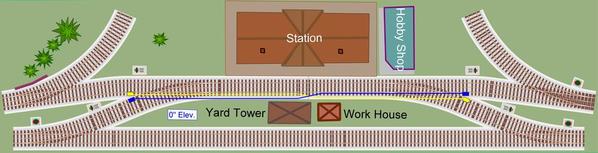

Here is how the wiring goes to automatically throw one pair of (remote/command) turnouts to enable the twice-around route to flow automatically. The non-derail feature of Fastrack is really a small contact detection on each approach leg to a turnout, so that as a train enters the turnout from either approach, the switch rails will change for that route through the turnout. Fastrack electrically detects an axle making a circuit across the detection point, which is a short insulated rail.

The other four turnouts are set for the correct routing and do not change as trains run the twice-around. The inside-main turnouts are set to straight-through. The outside-main turnouts are set to diverging (curved).

The wiring uses this detection strategy to throw the corresponding turnout in the opposite direction (note the different colors and wires crossing). Its as if a "ghost" train is detected at the other turnout to set the turnout direction. This will work for either direction of traffic (but of course all trains running either clockwise or counterclockwise) with the same pair of wires.

Adding a double-pole single-throw toggle allows you to make or break these two connections, to either set to the automatic routing, or not (normal function). No additional relays or complications needed - Cool!