WBC posted:WBC posted:gunrunnerjohn posted:Well, here's how those wires SHOULD have been routed if they had any brains. Saving an inch or two of wire created the whole issue with the flywheel!

When I do upgrades, that's how I run the lighting wires to avoid getting tangled up with the flywheel.

That is exactly how my phase II unit is wired. It has two harnesses which guides the bundle of wires around the motor flywheel. On my unit a couple of wires worked themselves out of the two harnesses. Brings up many questions. But one is: "what did the manufacturer know and when did they know it?" The appearance is that the manufacturer discovered the flaw in the middle/end of the run and corrected it but did not go back to correct the flawed units.

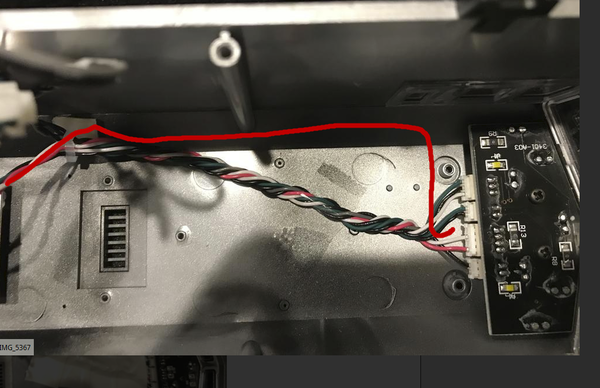

Here is an interior shot of my phase II unit, locomotive #200.

Clearly two harnesses that guide the cable of wires around the motor. Obviously at some point production changed. Did the manufacturer catch the error of the single harness and change to two harnesses? Or did the manufacturer decide to save a few pennies right in the middle of the run and change to the single harness system?

Anyways, my unit has the wiring arranged like gunrunnerjohn suggests and no major problems as of yet with about 18 hours of run time.

Im honestly not sure that really gets you out of the way. If you look up in the top of the cab with the lights on, the plugs are about even with the shield. The flywheel is a few hairs behind that, so the wires still aren't completely out of the way.

It sounds more to me like if the bundle is tight, then you're ok, but if its hanging down or has any loose wires at all, then you're going to rub through something.

All around, this just isnt the greatest design/packaging for the application. The plugs would have been better off located toward the side of the board, not the middle, and a different cable run (or even cable design, such as a flat ribbon) would definitely have been beneficial.

At least with the lion drive trucks, the motor is fixed in place independent of truck motion and doesnt rock around to create more interference.

I would love to see this service bulletin if someone can post it.