@Bob G (WNY) posted:...

I followed your suggestions and timed how long it took for the loco and tender to circle the track loop compared to that for this same unit pulling four passenger cars. Surprisingly, the latter time was only about one second longer; evidently the locomotive is moving as fast as it can.

Upon checking the locomotive speed limit control parameter for the Digitrax DC550 Command Station, I found that it was set at its factory maximum of SP99.

These findings seemingly indicate that I do need to add a power supply booster- -correct?

Have you measured the approximate length of your track loop? Since you measured the loop travel time at max throttle, this would tell us the scale-speed of your engine. It's not clear if you're looking to double the speed? Triple the speed? For 1/64 S-scale, an engine travels 0.275"/sec per scale-MPH. So if the engine runs 2.75 inches in 1 second that would be 10 sMPH. If the engine runs 27.5 inches in 1 second that would be 100 sMPH.

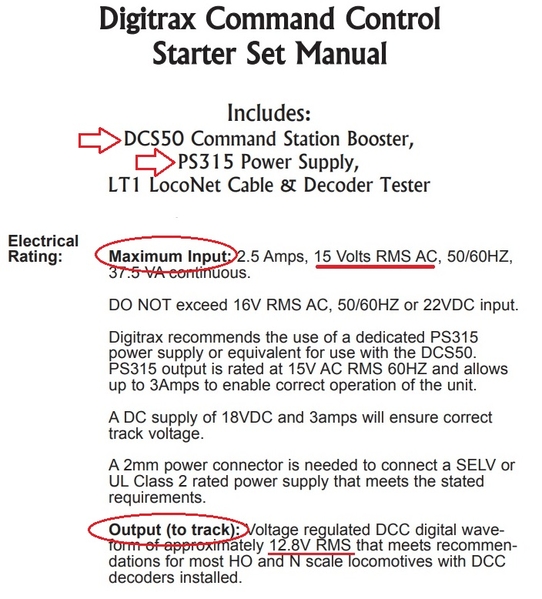

As Brendan above points out, you may be VOLTAGE limited. From the DCS50/PS315 manual, note how 15V (from you PS315) goes in, you "only" get 12.8V going out to the track. 12.8V would be rocket speed for an N or many HO engines ... I'm not familiar with how fast a typical S engine runs with 12.8V on the track. While it varies widely, I'd say an unloaded O engine with 12.8V on the track might run 40-50 sMPH. I'm wildly guessing an unloaded S engine should run, say, 70 sMPH withe 12.8V on the track? 70 sMPH is a good clip so I'm thinking you're not seeing that...but your timed loop measurement will tell us what you're seeing in sMPH.

Do you have a DC power source that is more than 15V? I'm not familiar with the type of plugs Digitrax uses so there may be some wiring hassle to power your DCS50 with a DC laptop supply or whatever.

From what little I read about Tsumani decoders, they appear to support Analog DC mode. In other words, you can run the engine in analog mode where the speed is simply proportional to the DC voltage on the track. It kind of depends on what you have and how much wiring hassle you can tolerate...but what I'm imagining is some way to simply apply some DC voltage to the track and see how fast your engine runs in Analog DC mode. This would take all the DCC programming 'stuff' out of the equation and tell us whether your engine has the underlying "raw" capability to go your desired speed for a given track voltage.