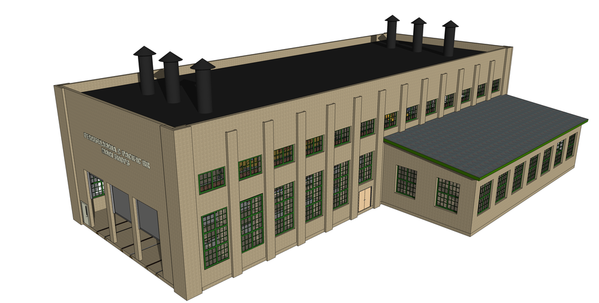

I'm still refining my custom design for my RR. I have a PRR S-1 and a C&O H-8 Allegheny which requires a 40" engine house. After toying with doing it in brick, the laser cutting costs were getting to high so I changed to "concrete". Right now I'm working with a vendor to get an estimate. Window cutting is $50. Building the trusses if I want them look scale with probably top $100.

I'm restrained from using any commercial product since I'm stuck with 3.5" track spacing resulting from using a ladder of Ross #4 switches. It's a feature (not a bug) that the Ross #4s ladder to a perfectly spaced yard system. It's just a little tight for engine houses.

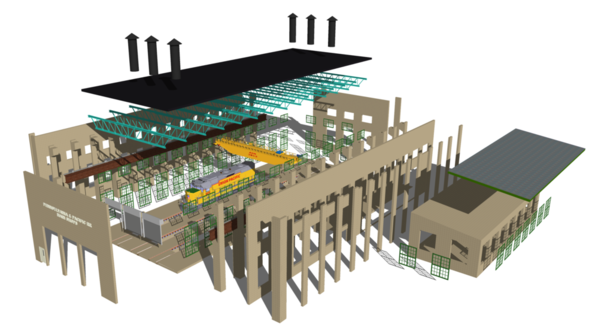

I took the building and exploded it in SketchUp to show the construction scheme. The outer buttresses are simply laser cut strips. The inner buttresses need to support the gantry I-beam and the roof trusses, therefore, they are more complex. I'll probably start with the same strips and then add some 3/4" square shapes to build up the bulk. Even buying the trusses from Plastruct would cost a lot of money. I'm trying to keep this project reasonable. The gantry crane will be scratch-built also.

When I actually get under construction on this (probably in a couple of months), I'll be posting it in detail under my regular 7 year build thread.

The design could easily be scaled shorter and it doesn't need the machine shop adjunct. So… if anyone would want a smaller version design for laser cutting, send me a private eMail.