Hi Bruce:

Regarding the curves, your choice is perfect for the elegant Pennsy catenary you are modelling. I actually did the same on a layout in a previous abode. I also used 18g wire there, with the aux and trolley separated by a small copper 'blip' soldered in between them to simulate the connecting clamp. It took forever to build that way. I decided my next system would be a bit more 'time efficient', as to actually run trains yet in my lifetime.

I am replicating the Amtrak structure you can see above New Haven to Boston:

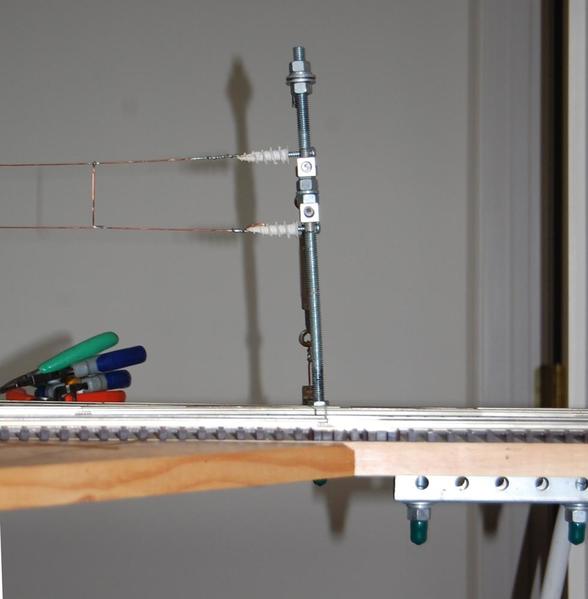

My wire and direct cat supports are built against this picture, and the cat supports are electrically insulated from the cat poles. The straight sections you see in my curves are all one wire strung around the curve, pulled off and then mechanically tensioned at opposite ends of a wire run, (out of frame). The pic below is an example pull-off. The wire tension bends 3/8" rod bolted to 3/4 benchwork with 2 metal base plates above and below. This is by design and the best way I found to keep the wire path in curves true.

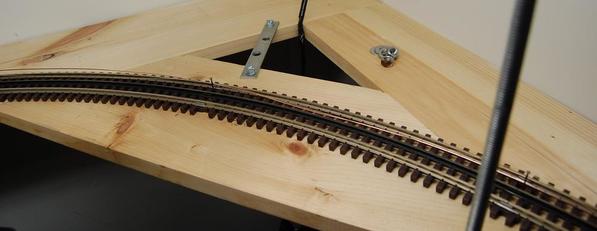

I understand your pantograph concerns, and planned ahead for that problem. Another reason for the 'straight-wire-in-curves' design was to encourage even pantograph shoe wear at speed. The issue of course was to keep the pans under wire. Stock pantograph shoes are about as wide as O gauge outer rails, as determined by those on Atlas O AEM7s and the long shoe of an MTH TRAXX 140. This became my template and I needed only to ensure the wire path stayed within the corresponding outer rail gauge. I was able to approximate the wire path using sewing thread and nails in the gauge along the entire track plan in a zig-zag pattern:

I erected the cat poles roughly 5 inches away from the center rail where the nails were. I then used the dummy AEM7 with a stock pan to measure height and width and ensure the wire path was right. The design of the cat support and poles allowed for adjustments along any axis to bring the wire path into line.

The final protection against "pantograph wander" is to build my own shoes out of brass, which are slightly longer than 'strict O scale'. They will replace the stock heads on the motors I run. I'm in the middle of that project right now, along with the control board.

Sounds like you had fun comparing GG1s. I haven't run them yet on this system, but I would want to do a very slow test. Even using O63 curves, a decent GG1 may push its pan out from under my wire in the curves. I've tried to build this so anyone's equipment can run, but I can only test for sure against pans I have.

As far as the sound goes, I've been quite pleased at MTH's sound board, at least in the TRAXX and new AEM7s; accurate and clear at higher volumes. My rail space isn't large, but the acoustics are decent.