Steven Michael posted:3/14/19-

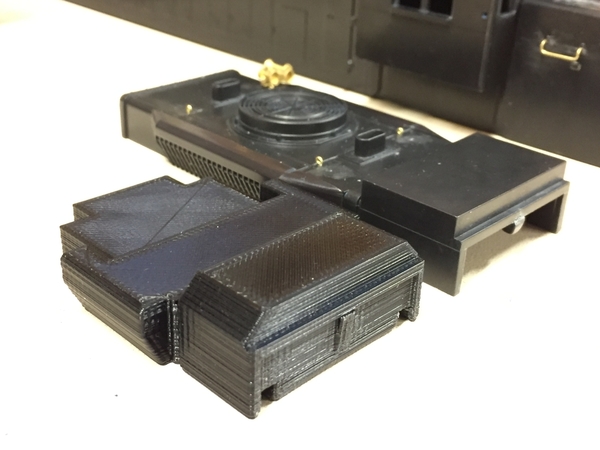

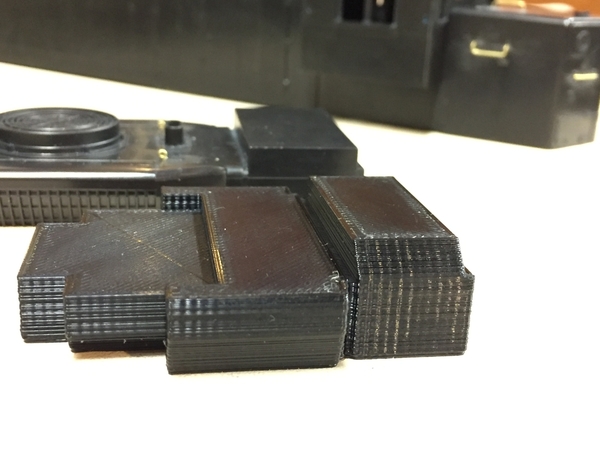

Got the new dynamic brake blister printed (thanks Charlie!). I changed the design of it slightly since I originally shared the drawing on here, for the sake of making the printing process easier. Here are some pictures of in alone and after trimming/in test fit. I haven’t glued anything yet, but as soon as I smooth over the print lines it will be ready for it.

<snip>

Nice job, Steven Michael. It appears that the dynamic blister was 3D printed using PLA filament. If this is so, please permit me to make a suggestion for the future. You might try using acrylonitrile butadiene styrene (ABS) copolymer filament in place of polylactic acid (PLA). One can smooth the surface finish of a printed part made of ABS by exposure to acetone (nail polish remover) vapor and save a lot of time sanding and filling. ABS is also a tougher, more durable polymer and it is the polymer with which the shell is injection molded. The principal use of PLA is in the application of biodegradable packaging and it is intended to purposely degrade over time via the mechanism of polymer chain scission (i.e., its molecular weight decreases).

Again, neat job so far. Enjoy!

Bob