Pete M posted:riogrande491 posted:As for the metal lathe I used, if you stick to P&D replacement parts you can do everything with just hand tools. I wanted to change the sprocket ratio for slower speed running. That helped when I used non-back EMF decoders. These days the motor control in the Loksound L is so good I won't change any more drives. The original drive ratio also produces less chain noise.

Because acetyl shrinks over time, there have been outbreaks of cracked gears in many vendor's products, even in certain runs of HO locomotives. Over many years stuff happens.

Question for Pete - Which Tang Band speaker did you fit in your GP9 and where did you install it?

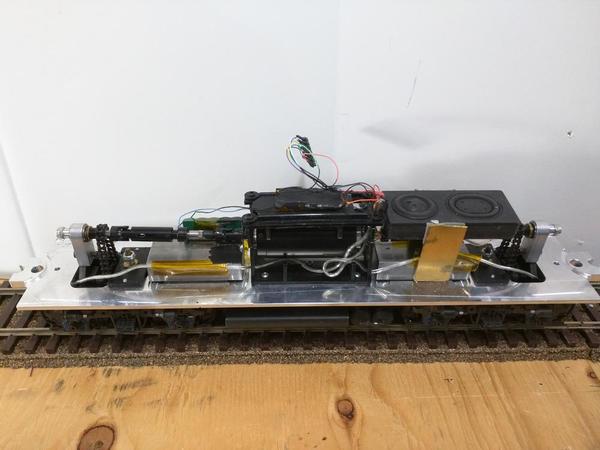

Bob, I took your recommendation and used the T1-1925S. Cut off the end tabs and fixed it on some side plate "legs" behind the motor and above the drive. I 3M taped them to the sides of the Finescale 360 weights. It just fits but I had to shave the inside edges of the plastic frame/walkway piece that sits on the metal chassis slightly to get the body on.

Excuse the spaghetti wiring, still in test phase, honest...

I am continually amazed and inspired by what you and your colleagues are doing on the A&O. Thank you!

Sorry for the thread drift and for attaching the photo with my post, but I'm hoping Pete will respond. I see you are using the machined aluminum frame from Kelly ? (IIRC) and wondered if you have discovered or decided on a way to attach the RC shell and sill to this frame? I've got the same frame that Jay C. has done a wonderful job powering, but I haven't discovered a simply way to mount the RC shell/sill to it.

Have you gone this far with your GP?

Butch