Perhaps you are referring to this recent OGR thread about station-stop operation for bump-n-go trolleys? In any case, the method shown there uses a more "sophisticated" (albeit more expensive) delay relay module that, for example, has a mode where you can set two time delay intervals which can be applied with benefit in station stop applications.

The relay module you show is a so-called "Delay ON" module. It has a single time delay. From the eBay listing:

Clearly a translation from another language but here's how it works:

1. Apply 12V DC to the input terminals

2. The module starts a delay (settable from 1-10 sec)

3. After the delay the relay turns ON. The relay remains ON until 12V DC is removed from the input terminals. If 12V DC is lost when the relay is ON, the relay immediately turns OFF. If 12V DC is lost when the relay is OFF (i.e., during the 1-10 sec delay), the relay stays OFF and the time delay starts over when 12V DC is restored.

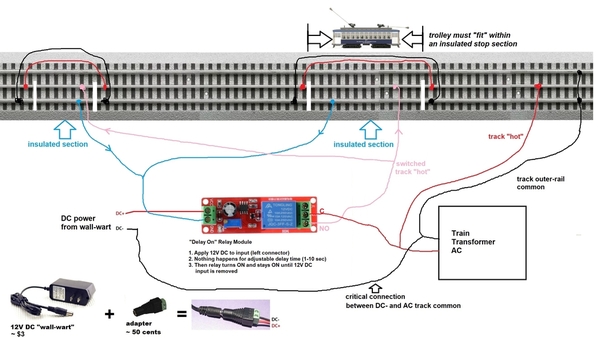

In principle, you could accomplish a station stop with this relay as follows:

This is a cut-paste modification from the linked thread which uses the aforementioned dual-timer relay module. In an ideal world, here's how your single-timer module could work:

You have insulated sections (center rail AND outer trigger rail) that must be long enough to accommodate a stopped trolley. In normal operation, there is NO power to each insulated stop section. A moving trolley approaches an unpowered stop section. Since there is NO power in the stop section it coasts to a halt. While in the stop-section, the trolley wheel axle(s) provides DC- to the relay module which starts the 1-10sec delay. Then the relay turns ON which applies center-rail power to the trolley and sends it on its way and out of the insulated stop section.

But here's the thing. This requires essentially flawless electrical contact between the wheels and the outer rails. That is, if the outer rail contact to the wheels is momentarily lost (for even a fraction of a second), the relay might hiccup/restart. Trolleys can be relatively lightweight and with the insulated rail triggering method you give up half of the wheels that pick up outer-rail power. It's a YMMV situation.

As with the linked configuration, a single relay module can perform the identical operation for multiple stops.

As for junction crossing, do you mean collision avoidance at a crossover? I guess it depends on how sophisticated the "algorithm". That is, for multi-train block control with Red-Yellow-Green or stop-slow-proceed logic, there are 3 choices of what to do depending on block occupancy ahead. Likewise, I can imagine a scenario where a trolley approaching a crossover slows down or even stops. Then proceeds if the "intersection" is clear. In any case I'd think a SPDT relay like the one in your module would be involved since it steers power to only one of two outputs at a time.