@Ukaflyer posted:Although the Z1000’s work fine do we know what the differences are internally between them and the Z4000? Could the Z4000 have boards that are designed to take into account the frequency coming in for specific functionality?

I did notice on the MTH website that it says the Z1000 is for 60Hz and the Z4000 doesn’t mention frequency at all.

Is it worth throwing MTH an email asking if the Z4000 is 50Hz compatible?

Let me see if I can tie together a couple of various topics and comments in this discussion.

The ways to create a variable AC voltage from a fixed voltage.

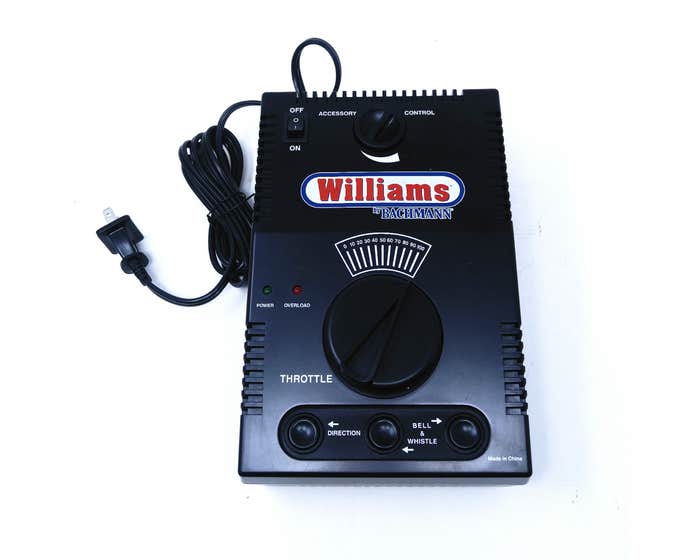

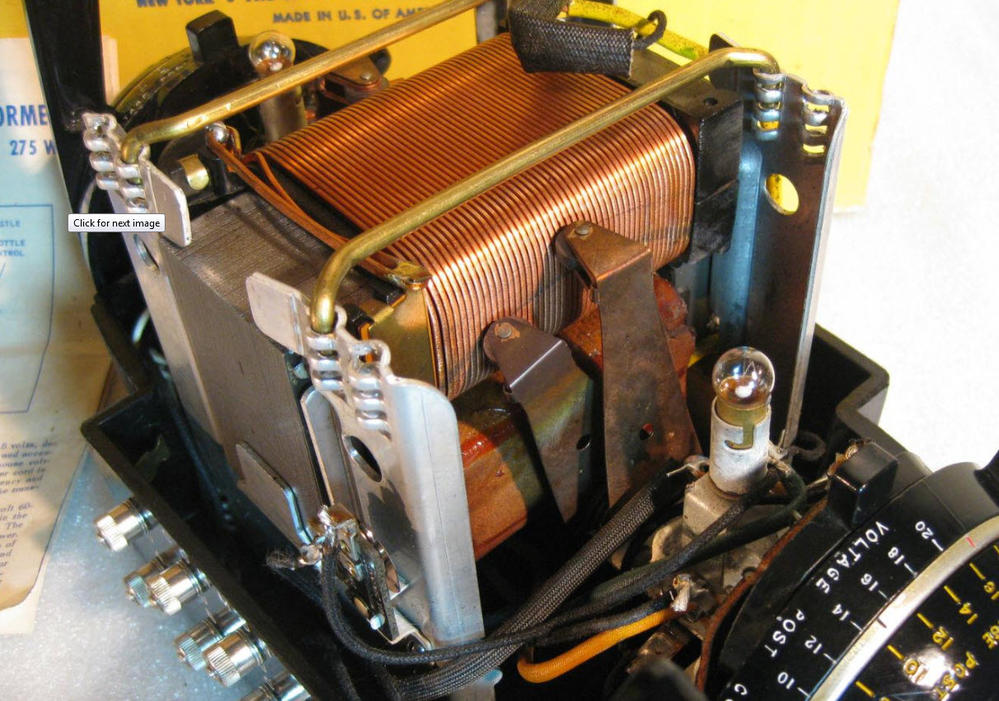

#1 The old school way- a transformer core wound with exposed secondary windings that a roller or wiper can tap into ever increasing turns of windings thus increasing the output voltage. Basically every postwar transformer and a few and somewhat limited selection of modern ones. Example MRC made the MRC Pure Power AC transformer, model AH501 or the ATLAS and rebranded Williams 80watt are 2 I know of with this type of construction.

#2 Rheostat variable resistor. The problem with this is that a massive amount of energy, sometimes as much as 50%, is turned into heat. So if your train uses 3Amps of current at say 12V, then we might be dissipating about an equivalent amount of heat 36 Watts. This is why are are not commonly used in O-scale because at the power level many trains need to run, the heat loss in the rheostat that it has to dissipate is dangerous. Think about a 30 watt soldering iron as a reference point.

or a more modern 25 watt rated example that probably would fail

or a more modern 25 watt rated example that probably would fail

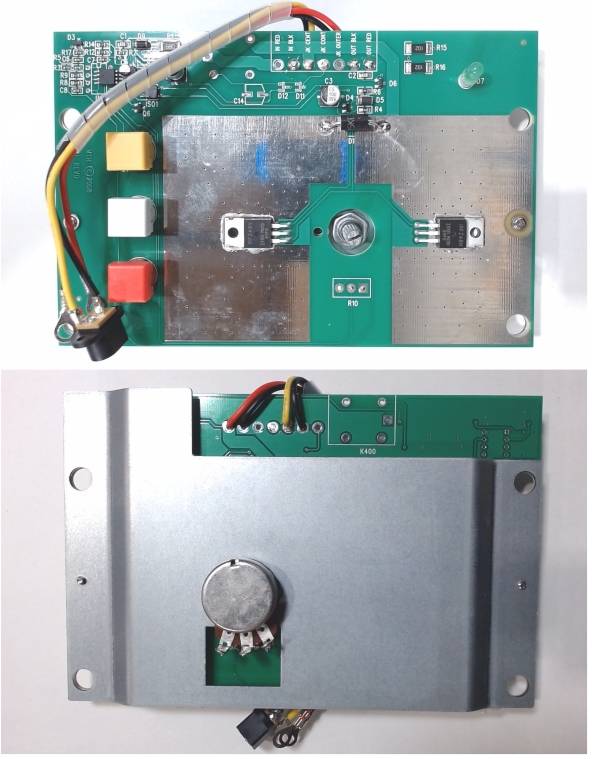

#3 Electronic control using a "Thyristor" which can also be a TRIAC, or other similar component. A key feature of this is that it is a transistor that has a gate that turns it on and in most cases, it stays on until the voltage across it goes to 0 known at the zero crossing. They use a circuit to delay the triggering on state to clip the original source AC waveform. In other words, they are cutting out part of the AC cycle and thus this causes distortion from the original wave form. This is called chopping. Again, while the thyristor or TRIAC is a major component, there must be supporting circuitry to change when the device turns on during the waveform. Examples that use this are K-line Powerchief 120 watt, Lionel CW80s, MRC 027, just to list a few. Again, these are not recommended for MTH PS1 electronic engines because they create a pretty distorted waveform. These are often obvious because there is only one large heatsinked transistor device (typically a TRIAC). A CW80 has one TRIAC per channel since they have a track variable channel and an aux power power output.

Another example is an MTH early Z controller that only has a single TRIAC (Q2015L5) in the center that mounts to the aluminum heatsink

#4 The more advanced method of using 2 (or more) MOSFET transistors per channel to handle the negative and positive swing of the AC waveform. That said, they still need advanced circuitry or a microcontroller to sense the AC incoming wave and then time and trigger the gates of the MOSFET transistors to conduct a specific portion of the waveform. The idea is, more components and details, but better control and smoother output than a TRIAC based output.

Modern recent MTH Z controller uses 2 MOSFETS instead of the previous single TRIAC.

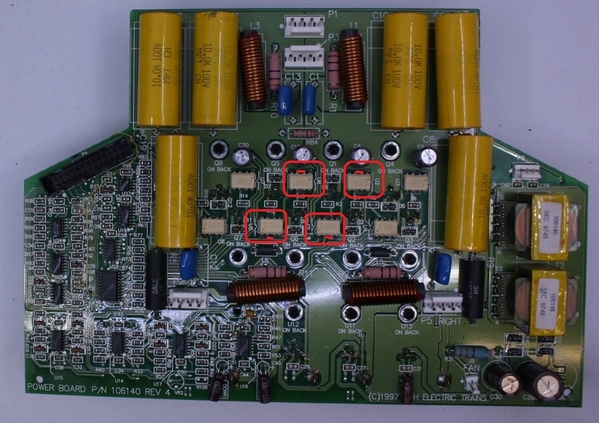

the Z4000 power control board. There are 8 total MOSFETs for the 2 channels.

and the FET side that faces the heatsink

and the FET side that faces the heatsink

And then the front panel board that drives the power board