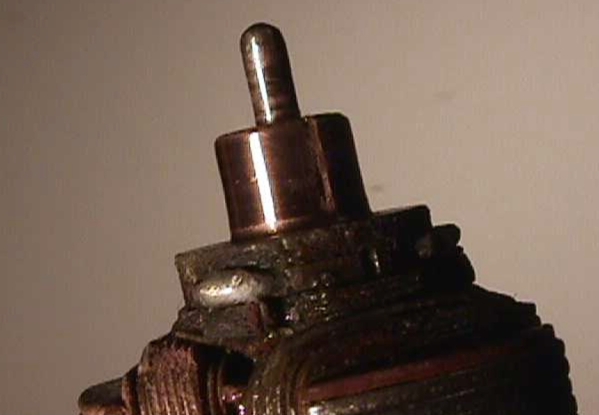

Mark sounds like you have an older style “Barrel” commutator.

Here is a link that discusses the importance of the phenolic washer, which holds the three commutator segments together, and how to epoxy them if its broken. It sits above the solder ball on the left side of the pic, on top of the horizontal lip of the segments.

You should inspect this to make sure you aren’t going to have a blown commutator.

https://ogrforum.ogaugerr.com/...matures-commentators

Here is a pic of an engine I had picked up that suffered from a broken ring.

Fortunately all three segments were still in the motor. I was able to clean this up, and used a ring of heat shrink tubing in place of the ring. I also placed a drop of super glue on the back of each segment to the shaft. So far so good with its performance. Unfortunately I hadn’t taken any pics of the finished product