I have been going through my fleet of 8976 switchers. In looking at a 227 yesterday it noted it had a broken side rod. Thinking changing the side rod would be a quick fix, I got right to work. With the side rod off, I immediately noticed that one wheel was freewheeling on the axle. The loose wheel probably contributed to the broken side rod.

To change the wheel requires stripping the entire frame, so I got to it. The axle had been hammered on enough to peen the end over. I assume this was an effort to tighten up the loose wheel. But it made removing the wheel more difficult and damaged the bore as it was pulled off. I ended up pressing two new wheels on a new axle. With everything new and properly sized, the work went quickly. When changing only one wheel set l do not use the lines scribed in the wheel cups. I lock up the lower cup and put one of the wheels not being disturbed in it. Then I lower the press and, with the upper cup loose, I line the upper cup up to match the existing wheel. Then I lock up the upper cup. This way the replacement wheels will match the existing wheels exactly.

The cross head guides were bent down about an 1/8” on one side and a little less on the other side. I have never seen this before. I considered trying to straighten the guides. It quickly became apparent I was going to make tooling to be effective. To keeping moving along I decided to use a new steam chest I had in my parts box. This fit in the valve guide support assembly better than I had ever seen before. It was conformation that these two parts need to be fit together, and adjustments made, prior to assembly.

As with most 8976 switchers, the wire to the front coupler needed to be changed. I disassembled the front coupler and installed the new wire. The more I do this the better I get at it. This use to be the job I hated to do, but now it is just another repair. I also overhauled the motor. It was actually in fairly good condition, except it had been lubed with white lithium grease that has turned to glue. When removing the motor I noticed the fiber spur gear was missing one tooth. This has to be replaced

With everything back together and running very smoothly, the only thing left to do was service the e-unit and test it. It was in good shape, but when testing it, it failed to operate properly about half the time. The OO e-units are usually very reliable. I will take that project on tomorrow.

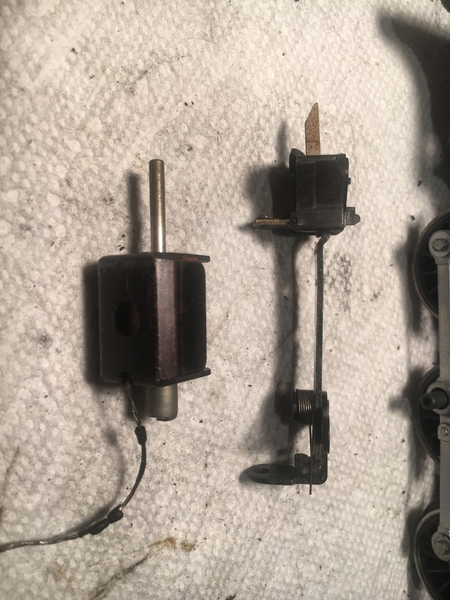

Following are a few photos illustrating the days adventures.