More on the 227 prewar 0-6-0 switchers, except this one happens to be a 230. I recently acquired this loco and after cleaning old grease out of the gear box it was making growling noise and sometimes locking up when turning the wheels by hand. Closer inspection revealed that the idler gears, the ones on the side of the frame between the drivers, were loose on their stub shafts and were cocking and rubbing agains the edge of the drive wheels. At times the gears would jam against the edge of the wheels locking the mechanism. Below is a video of this problem taken on another locomotive. At that time I swapped out the frame with another engine which was not going to run any more.

Next thing to do was to pull the wheels off in order to remove the two idler gears. I used the Lionel ST-311 wheel puller, which worked well as there is lots of room between the wheels and the frame. The center gear side wheel was pulled to avoid having to remove the worm wheel in the middle of the center axle. Normally the best practice is to remove the non gear side wheels, which is what was done on the outboard wheels.

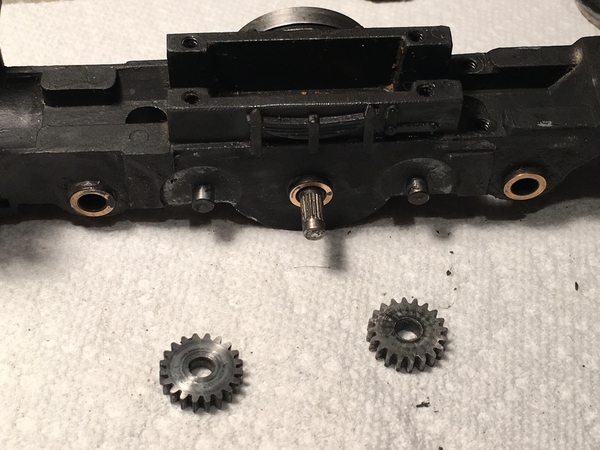

With the wheels removed the bore of the gears and the diameter of the stub shafts could be measured. The normal ID of the gear bore is 0.160". These gears measured to be 0.165". The stub shafts should be 0.156" in diameter. These measured at 0.153". The design clearance between the gear and the shaft is 0.004". On this loco it clearance was 0.012". Three times what it should be. I also measured the axles and bearings. The axles were right on the new axle dimension and the bearings were only a few thousandths oversized, so I let them go.

I found that I had new stub shafts and gears, so the plan was to change both. Fortunately when Lionel design this loco, they put holes in the frame across from these shafts, making it easy to use a small pin punch to knock out the loose shafts.

These are the worn out stub shafts and gears after remove.

I found two different looking stub shafts in my parts supply. I was able to determine that the upper stub shaft is a modern Lionel part from the 1990 remake of the 227. The lower part is an original part from 1939. I chose to use the lower, original, stub shaft parts because it has a slighter smaller serrations on the shaft that would make it easier to install. In addition to being pressed in I used Loctite 640 sleeve retainer to provide some added strength and try and prevent it from coming loose in the future. First I cleaned the hole with acetone.

Then I applied Loctite SF-7649 primer. The small end of the stub shaft and the inside of the hole were then coated with the 640 material.

The pin was tapped in with a hammer and it went in square and secure. At this point I cleaned up the area around the shaft and left it to harden for 24 hours.

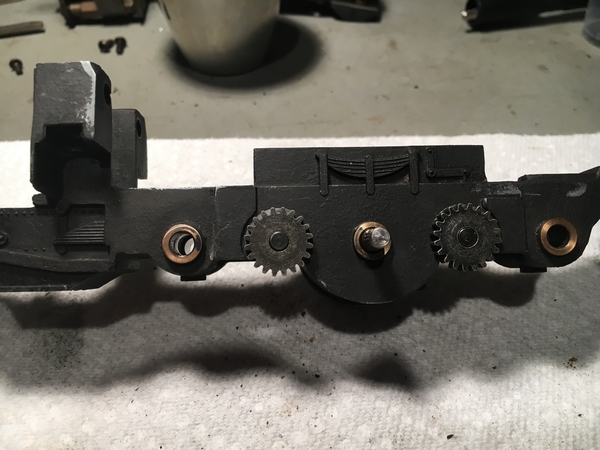

This shows the new gears on the new stub shafts ready to have the wheels reinstalled. Putting the wheels on is the tricky part of the repair. First the center wheel has to go on the gear side, which means I have to press the wheel on while getting the new gears to mesh with the gear on the back of the wheel. The gear on the wheel is zinc and could be easily damaged by the steel idler gears if I tried to press them together while the teeth were misaligned.

After the center wheel was pressed on the two axles with the geared wheels can be slid into the bearings. A side rod is used to get the gear mesh correct for the two outboard wheels. First one outboard wheel is installed with the correct gear engagement so the side rod fits on properly. Then the wheel is held in place while it is put onto the wheel press and the non geared wheel is pressed on the other side. This is repeated for the third wheel set.

This photo shows the third wheel set in the press ready to have the non geared side wheel pressed on. The wheel cups are designed specifically for this locomotive and they get the proper quartering on the non geared side.

Here is the project all finished running on the test stand. Next step is to rewire the loco and rework the tender. A couple of days work to go and another 0-6-0 will be back in service.