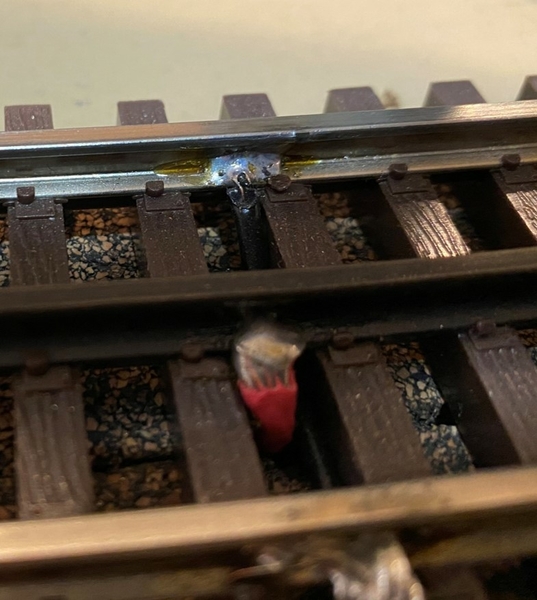

@Rich883 posted:Here is a photo

I drill top down at an angle. You can see it does not melt the ties.

Now I agree with Hot Water and some of the others, you can solder to the rail with out drilling as long as you burnish/ rough up the spot you want to solder to. I have done this, however I found that I really needed another hand to hold the wire tight to the rail, and I had the soldering iron in one hand, and the solder in the other.

This approach, at least for me, killed two birds with one stone. It created a fresh clean surface for the solder to bond to (inside the drilled hole) and it created a holding mechanism for the wire while I soldered it in place. It also created the smallest point of solder you can see, I found laying the wire against the rail had a longer portion of wire exposed.

Lots of ways to accomplish the same thing, this one just works well for me.

I like this idea and am wondering if this has been tried on tubular track? However, my solder is not adhering. Thinking about trying flux with it? This is what I am using with a Sealody Soldering Station.