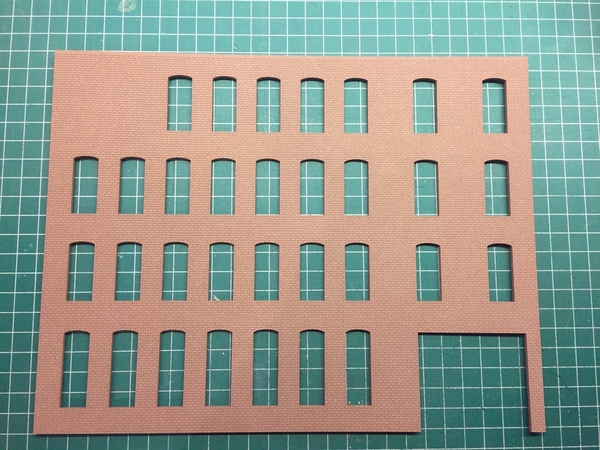

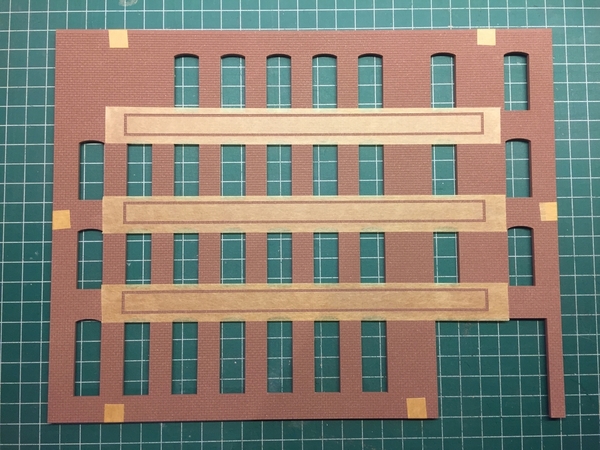

Lettering on the D.F. Stauffer Biscuit Co. building- here is how we do it- the first half of the process. Basically it is a 3-step process of using the laser to cut the masking. First for the red band, and second for the letters. A template is cut in the laser bed to match the elevation piece. Note the masking tape on the edges of the elevation. We do that to make up for the laser beam width so the piece to be recut fits exactly in the same place in the bed. This is how we get the red band to lineup on a brick course. The elevation is put in the laser with the masking and the red band is cut. It is then painted and let to dry. The masking is removed and a fresh piece is put on. The next step is to cut the letters. That is the last picture in this group. The next step for us is to paint the letters white.

OGR Forum Supporting Membership Required

Access to this requires an OGR Forum Supporting Membership

OGR Forum Supporting Membership

Help support this forum with an OGR Forum Supporting Membership.

You will be able to watch the videos in the INSTRUCTIONAL VIDEO FORUM!

A one-year OGR Forum Supporting Membership is only $12 per year, so sign up now!

OR

Access the ALL the OGR VIDEO FORUMS AND over 300 back issues of OGR

with a DIGITAL SUBSCRIPTION!

$12.00 per 12 Months (plus tax if applicable)