I'm finishing up an upgrade on a 3rd Rail Big Boy, and on it's final test run, a problem surfaced. I know I've seen this discussed before, but a search didn't turn up anything definitive on the exact details of a solution.

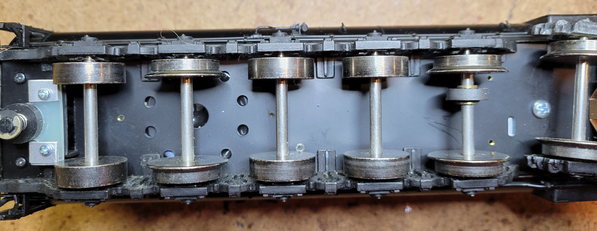

The blind wheels on the tender short on about half of my Ross switches, and it's easy to see why. They're considerably wider than the flanged wheels, and they also don't have the flanges to keep them from moving toward the center of the track on turns or even going straight.

The "cure" appears to be to taper the surface of the wheels from the inside edge to maybe 1/3 of the way in so they will not contact the center rail extension that bends toward the outside rail.

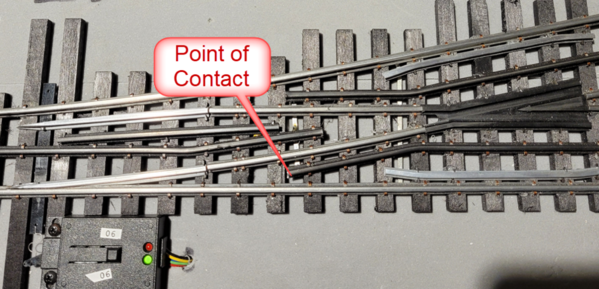

Here's a typical switch that causes the short, most of the switches have a similar shaped rail to reach out and contact these wheels.

The question is, how far back should I taper the wheels, and what angle should I use. I want to have the taper not be so extreme that the wheel will catch the rail and cause issues, so it needs to be a fairly gentle taper, but enough to keep the wheel from contacting that center real extension. I'm thinking about 1/3 the width of the wheel, but I figured it was worth asking here to see if anyone has a better plan.