Improve short locomotive wiring in 7 steps

By Peter H. Riddle | March 29, 2021

Stuttering through switches can be fixed with this one-night project.

(I'm adding this story I found to help anyone else who is experiencing a problem with short foot print pickups...kk)

I hope it helps.

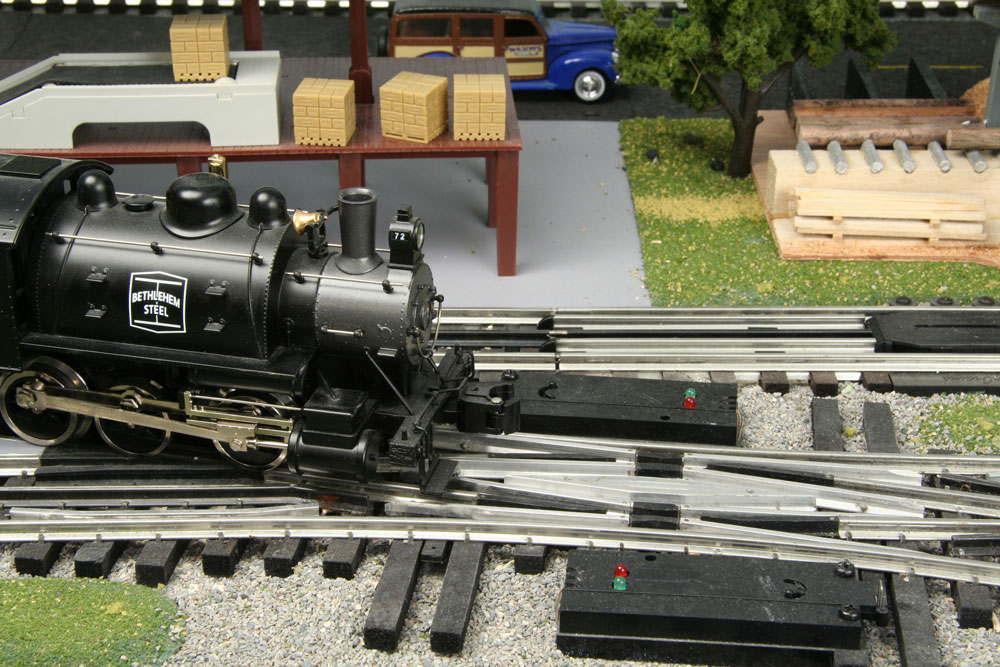

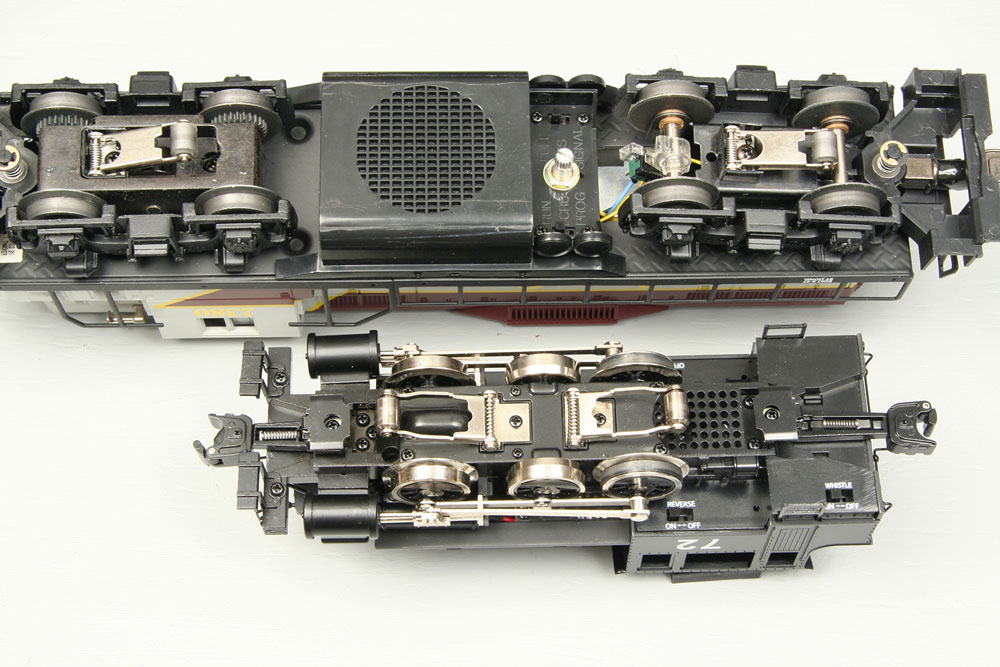

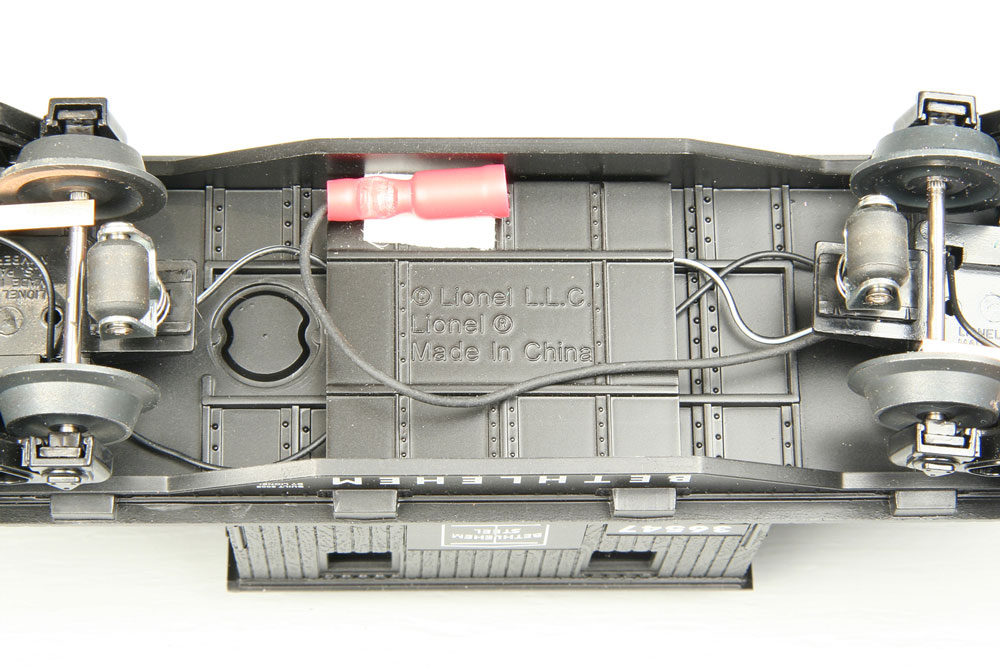

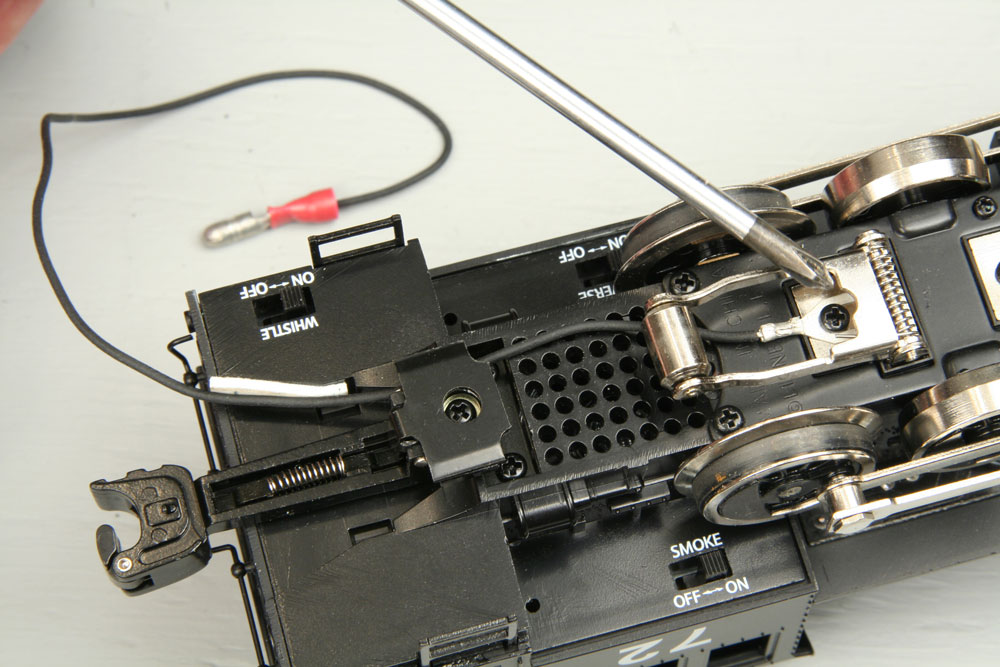

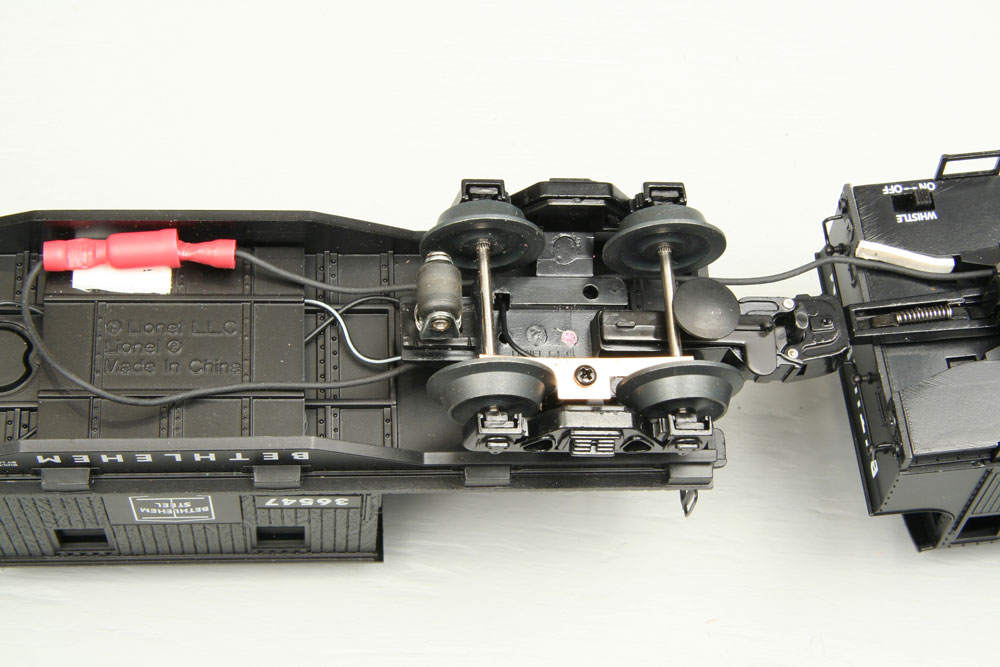

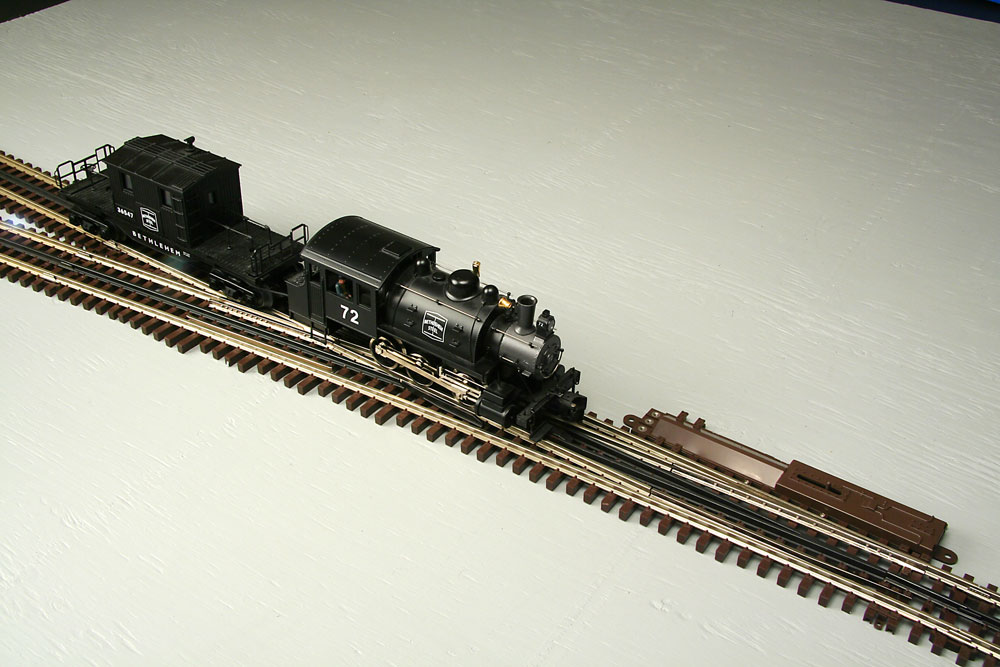

Some of today’s short-wheelbase locomotives have issues with the prototypical switches and narrow-angle crossings that make an O gauge railroad look realistic. Here’s a quick fix that will allow any locomotive - even this economical Bethlehem Steel saddle tanker from Lionel – to perform reliably over the troublesome trackwork.

Supply list

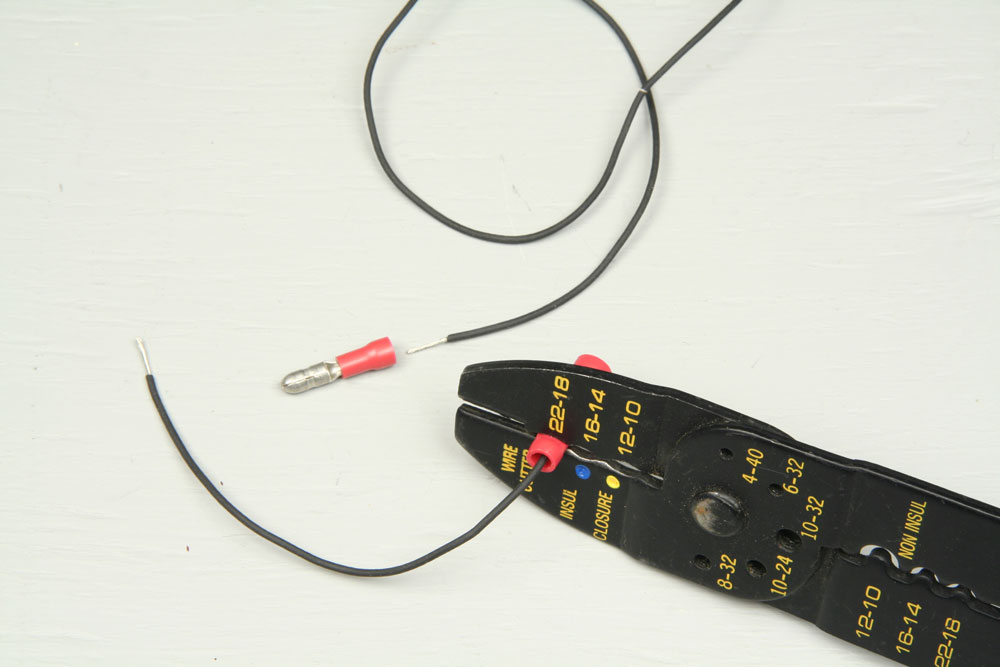

22- or 24-gauge wire

Male and female solderless connectors

Crimp-on spade connector

Screwdriver

Soldering iron and solder

Two-sided tape

Wire cutter/crimper