Other stuff I've learned through experience.

On a whim I picked up a Lionel PW 282 Portal Gantry Crane and found a home for it on the PER. A real-live operating accessory:

It migrated across Oil Creek to the East End as that industrial area evolved and grew:

But every time I operated it I was struck by a deficiency: when you reach into that miniature world and give the Crane a shove (several times to load that Gondola) the illusion/caricature is destroyed. I set out to give the Crane remote traverse (along it's rails) movement. Having another 282 on hand that was in pretty rough shape I determined to use it's guts for a traverse winch.

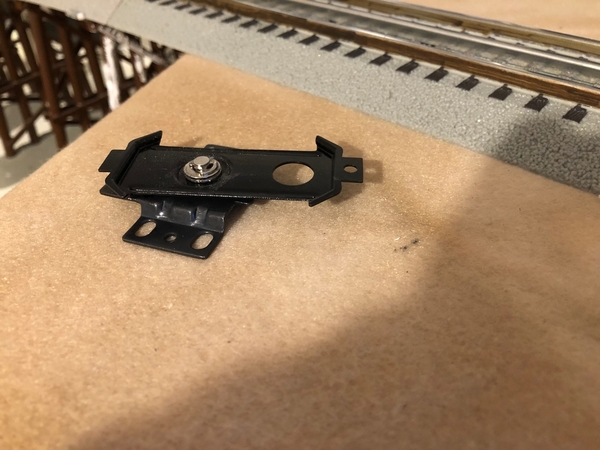

The first step was to reduce the crane cabin base to the essential bit. From this:

To this:

Then remove the unwanted bits from the base:

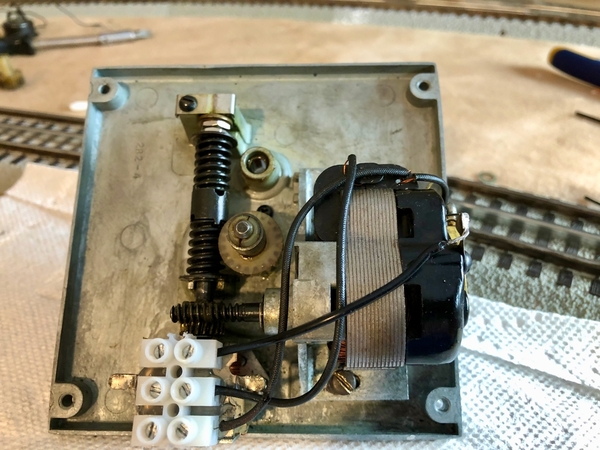

Reassembled, we have a power winch:

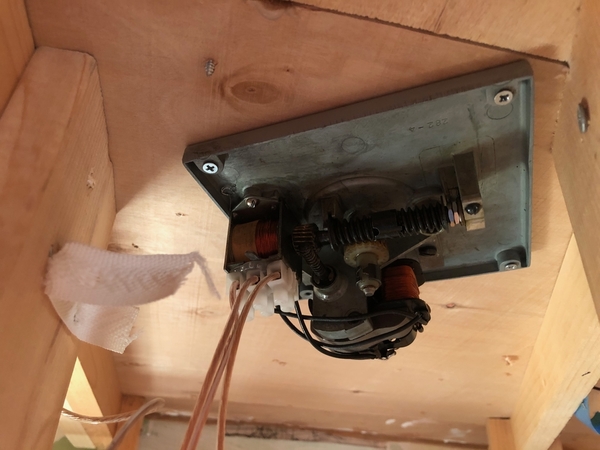

Installed under the deck:

With the business-end above the deck:

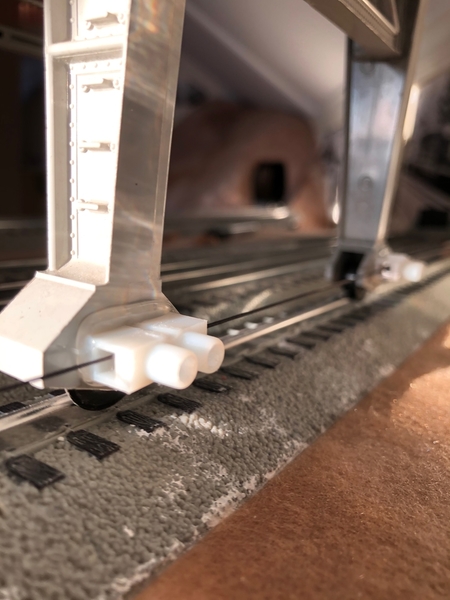

The cable strung and attached to the Crane legs (that is part of a wiring terminal-block hot glued to the leg):

A pulley redirects the cable to hang vertically and under the deck a weight is suspended which applies tension to the cable in counterposition to the winch take-up drum:

The winch-house:

In this pic you can see the whole setup with the winch house to the right, the redirect pulley at the left and the cable strung between. It works well and surpasses expectation by adding a whole dimension to the operation of the Crane. With all functions remotely controlled the operator has the ability to move any scrap anywhere.

There are three 70ft K Line aluminum passenger cars in service on the PER:

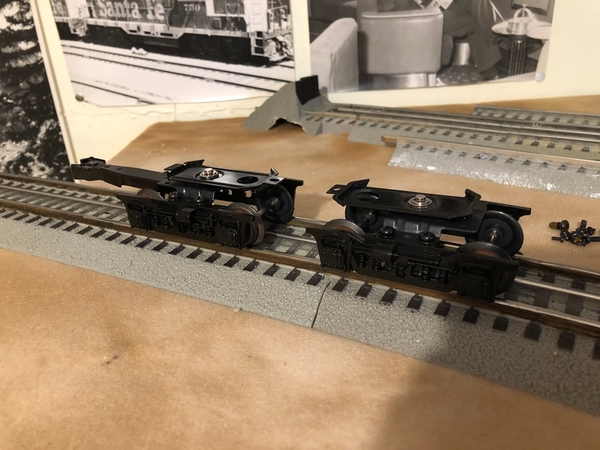

Of the three, two have a case of the wobbles. That is, they don't sit stable on their trucks but rather wobble from side-to-side disconcertingly when in motion. I quickly changed out a pair of good trucks and put the business car on the line but I wanted to see if I could do a repair. If I have two cars doing it there are probably a thousand out there with the same issue. So I dissected the trucks completely including driving out the center pins.

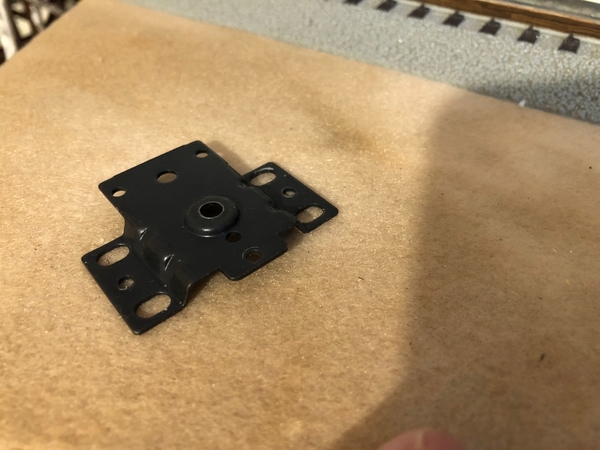

And there is the problem:

The hole for the swivel-pin is punched (poorly) rather than drilled (saves pennies) leaving a bulged surface as a swivel-bearing plate. Hence the rocking back-and-forth. So I punched that dimple back flat and dressed it with a nice flat file:

Nice flat mating surface.

BTW, any truck with a coupler must have the coupler-centering bracket bent up to allow access to the truck mounting pin and then bent back flat when the pin is driven home again:

A nice fit with no wobbling or rocking:

Ready for final assembly:

And there you have it.