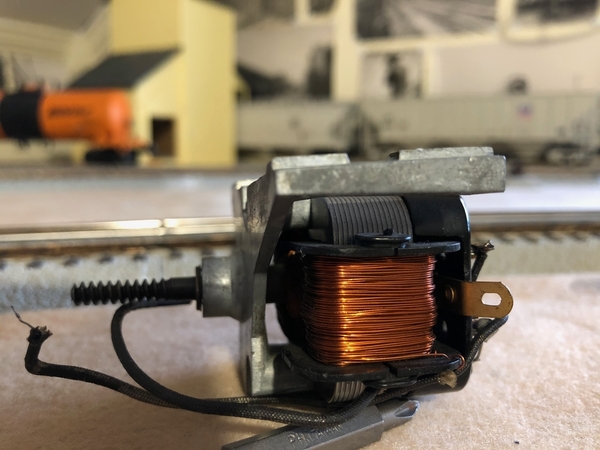

Mike, I took some pics of a "spare" 282 motor to show the gear-lash adjustment.

Notice the taper of the motor mounting pad (motor is upside down):

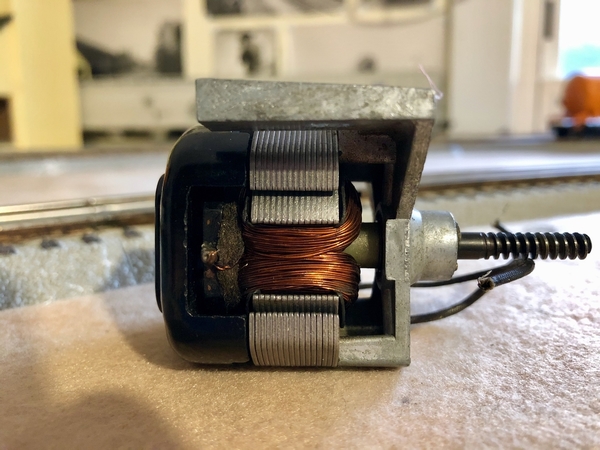

Again from the other side:

And the slotted mounting screw holes to allow the motor to slide on the pad that is machined into the crane metal baseplate:

So because the motor (and thus the worm) is tilted wrt the mounting pad, as you move the motor back-and-forth the worm gets closer/farther from the worm-pinion and the lash becomes less/more. The question is, does the 182 motor do the same thing or was this a design improvement between the 182 and the newer 282 Crane?