There is an alternative to 3D printing but I was hesitant to post it for the following reasons...

1. Would there be Licensing or Copyright issues with Bachmann if replacement parts are created and sold (versus giving them away),

2. The parts creation process I came up with requires more testing to refine the process.

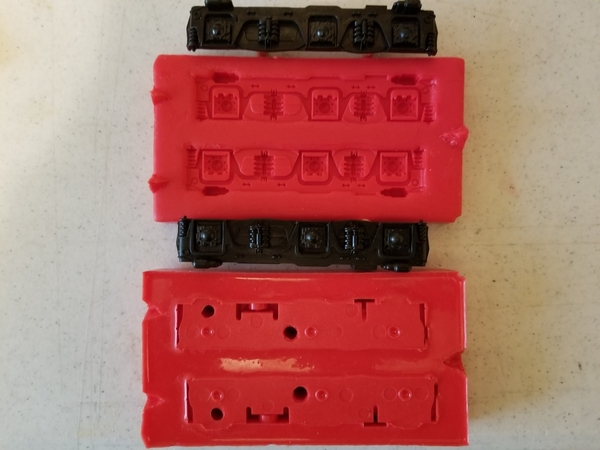

Several days ago, I created a test silicon mold using the side frames from my William's (not WBB) Trainmaster...

This mold was my first attempt ever at creating a 2-part (front and back) mold. I was surprised how good it came out!

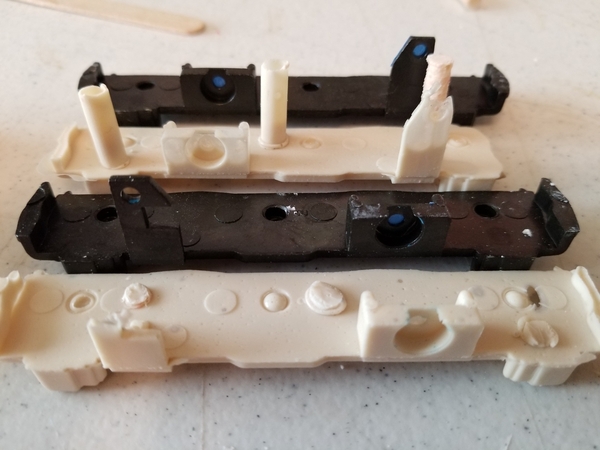

I then did a test resin cast using the resin that I had on hand. The results were pretty good but not quite "ready for prime time". I just wanted to see if it could be done. Here's the results....

As you can see, some sections of the resin copy are missing for several reasons....

1. The missing sections are deep inside the mold. As a result they need to be prefilled before the mold halves are brought together and the remainder of the mold is filled via the fill tubes.

2. The resin I had on hand has a 2 MINUTE work time that begins once the 2 parts are brought together. This is what happens if you move to slow...

The resin harden in the cup as I was pouring it into the mold!

I think this process will work once I find a resin with a much longer work time. But that will present it's own challenges too. That means more testing.

But I'm willing to try if you all want me too.

Let me know what you think.....