JD_Reith posted:.. I'm not at all afraid of wiring and trying things. I spend most my days working on DC systems on Agricultural equipment, but for some reason AC really throws me for a loop doing these things because I'm not as familiar with the components.

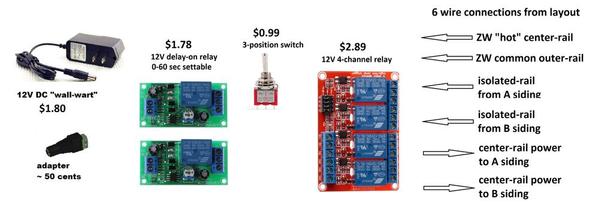

Not to worry. What I'm imagining is a DC system (12V) with all the logic, timing, etc. being performed with off-the-shelf 12V DC relay and timer modules. I was making some chicken-scratches on the proverbial back-of-an-envelope and I'm thinking maybe $10 (free shipping) in eBay modules and parts.

I'm imagining 6 wires from the track/layout as shown below. ZW "hot" power would be switched to the A or B sidings which means you would need to isolate power to the two sidings using insulating/fiber pins to create power blocks. Additionally, within each siding, you would create a section of insulated-outer-rail which would be used for occupancy detection which triggers the swapping of center-rail power to the other side. A 3-position switch selects A-only, B-only, or alternating A/B operation. The relay modules would be powered by a 12V DC wall-wart. I think it can be done with minimal soldering (perhaps just 3 solder connections to the 3-terminal switch).

The relay modules have screw-terminal inputs and outputs so no soldering required there. The trick of course is defining the inter-connections between the modules.

The basic idea for automatic alternating operation is as follows. The mainline is always powered. Suppose siding A is powered. Trolley A leaves the siding enters the mainline and when it returns to siding A it trips the A-side isolated-rail and power is swapped from siding A to siding B. Trolley A stops. Trolley B starts up. Trolley B has to run to its bumper, reverse, and then leaving siding B. This takes, say, 10 seconds. The "trick" is to disable the siding B occupancy sensor until trolley B has left the siding and has entered the mainline. That's the purpose of the time delay relay modules which waits, say, 15 seconds before enabling the occupancy sensor on side B. Non-derailing in the turnout switch will automatically set the turnout direction as trolley B enters the mainline. When trolley B returns to siding B, the occupancy sensor has now turned on and power is swapped from siding B back to A. Lather, rinse, repeat.

I figure about $10 out of pocket. Anyway, does this make any sense at all? It is somewhat involved and as suggested earlier, is DIY rather than plug-and-play. I can provide additional details if your eyes haven't glazed over. ![]()

Of course if someone else has a simpler solution, let's hear it!