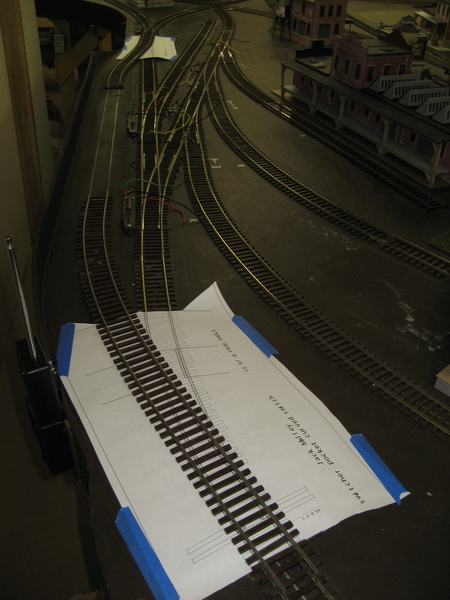

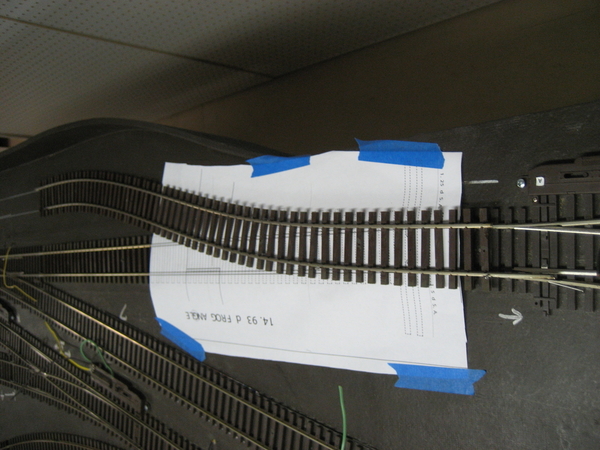

Following is how I normally get switches made. First I make crayon tracing, then I receive C.A.D. of the turnout full scale and have FedEx print it for me 1:1. Then I lay it in place to confirm rail alignment. After confirming exact fit I OK it's fabrication. Brad is batting 1000 at this point. Every switch fit perfectly. Probably about 50 one of a kind turnouts and a few pedestrian #6's.

The tight yard situation needed switcher runaround so we spliced in an extension.

Templates check out for accuracy.

Signature switch built with a built in curve before the points. Kinda weird but necessary. Mostly 40' boxcars and a small center cab so all can make the "S" curve.