OK, mine arrived this afternoon. I only had enough time to test run it, but here are some supplemental observations on top of what has already been revealed by forum members who also purchased these.

First, it does appear to be an FP7, minus the four louvers that are a telltale sign of such cab units from EMD. I checked dimensional data from Model Railroader Cyclopedia Volume 2 Diesel Locomotives to confirm the length coupler face to face (54’ 8”). Because O gauge couplers are oversized, I then measured the Menards locomotive from pilot to rear wall (53 feet) using a scale ruler. I then cross-checked it using the same measurement on an N scale Kato FP7, a meticulously scaled model. It measured 53 feet as well.

I also eyeballed the nose contour against the Kato unit, which again has been universally praised as accurate. The Menards unit compared well, spoiled only a bit by the indented pilot design. (O gauge manufacturers frequently get this contour wrong, dating back to Lionel’s postwar F3.)

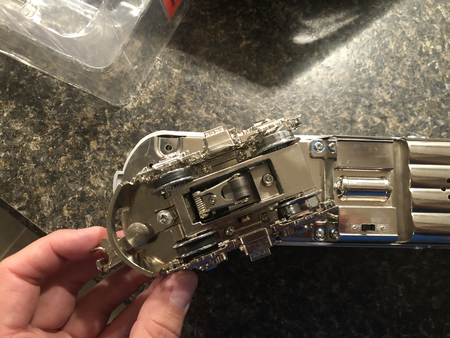

Check the closeups of the Kato model and the Menards model.

Then I did something that certainly won’t be my routine. I tested it on my 3-by-8-foot home layout featuring O-27 track and curves and a 90-degree crossing. It ran flawlessly, at least without any cars attached. So, yes, no problem with O-31.

Problems? Yes. The remote. Sure enough, like earlier reviewers noted, the battery contact strips were not reaching the positive poles on the batteries, thereby providing no power to the remote. The problem is that the batteries are actually contained in a plastic compartment with plastic slots on the positive ends to secure the batteries firmly. The metal strips (with the pole nubs) simply don’t reach far enough into those slots to make contact with the battery nubs. The battery fits tightly, but that’s misleading because of the design. The solution, as stated by others, is to simply bend the metal strips inward.

The packaging did result in minor abrasions behind the horns of the body, and the bosses (posts) into which the body screws secure the body to the frame are cast in such a way that they create small dimples atop the diesel’s nose. This is a casting problem, not a mold problem.

The running characteristics are as others have reported. I tested it with a Lionel BW-80 controller and brick. You can see for yourself how it ran in this short video.

I love the look of this model and like the way it runs, but it’s as basic as Menards intended for the price. Here’s a sideshot of the Menards locomotive behind the Kato FP7.