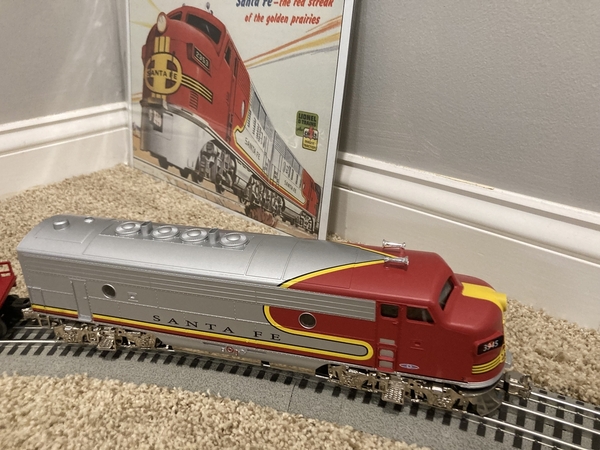

Wow. Missed out on this one. Hope Menards does a re-run soon.

Menards is a Big Box lumber/hardware/

building material, etc, store.

The toy train products are a sideline. I don't believe Menards aspires to be Williams, Weaver, Lionel, or MTH.

I have been thrilled to find rolling stock, and buildings at a pricepoint that makes this hobby affordable to all incomes.

The Menards market strategy of selling trains and hardware is a wonderful nostalgic idea. I find myself checking out the trains every trip for hardware.

I don't own one of these new F3/FP7/%^*.

I will when they restock.

So...my evaluation is based on the response of persons on this forum and personal satisfaction with previous Menards products.

Menards; If you don't change anything on this locomotive...I WILL buy one.

I am not interested in it being TMCC, DCC.

I don't need any Dolby hydrophobic bass sound. No...don't need a proto coupler or smoke ( diesels that smoke need repair).

At this price point this is a nice O gauge toy that has plenty of play value just as it is. Packaging is blister pack and that's been in use by N and HO gauge for years.

My 2 cents is:

don't cater to the "more is better" crowd.

" More is better" COSTS $$$.

I personally like the idea of being able to take my grand daughter and grand son to Menards to buy a basic toy train that doesn't break the bank. At the price this diesel was sold for the kids can handle it themselves and grandpa can teach them the basics and gradually let them play with the more expensive collection.

Lionel cornered the market on the word " Legacy".

Menards is selling toy trains and equipment to help keep this hobby affordable and further the "Legacy" .

So...as is..Menards

WELL DONE!

keep them comming.