It's been quite a while, finally got back to laying down track, trying out different ideas etc. After struggling with relays, trying to understand what wire goes where and having a few go up in smoke, went back to the old school way with fibre pins, lockons interconnected, a few pieces of insulated track, with a minor modification to fibre pin placement in one of the blocks, (stops one train further back allowing the second train to clear an O22 switch)it works as expected.

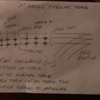

Will post an image of the track plan, from one of the old Lionel manuals with my notes.

Here are the two images, the first Track Plan 1 with reversing loops is what I have laid out, the reversing loop on the bottom is on the right side of the layout. I moved block "A" back a few track sections, this gives extra wiggle room for trains to clear each other.

The second is from my manual dated 1952, at one time before I started the current layout, I used the plan on the left on two sheets of 4x8 plywood, joined end to end to make a 16 foot length of track.

I'll have a 153ir around or before block "A" that will trigger a signal from green to red in block "A", but have a short duration, giving enough time for the train to clear Block C1, allowing the train in block "A" to leave, not jumping as the light changes to green, allowing for a few seconds of delay, if that makes sense.

Not sure if Lionel ever put out a book/manual off all these old track plans that use this simple technology. The beauty of this is these simple plans can be modified without difficulty, ie: the plan from Track Plan 1 on the right is the same as the plan on the right from Track Plan 2, the reversing loops have been moved outward rather than inward.

Thought I would show the progress on this layout build. It’s a cantilever design, no legs on the floor. Started out as a circle around the Christmas tree 1964, will have to post that photo.

Thought I would show the progress on this layout build. It’s a cantilever design, no legs on the floor. Started out as a circle around the Christmas tree 1964, will have to post that photo.