Woods Warehouse Craftsman Kit Build – Post 8

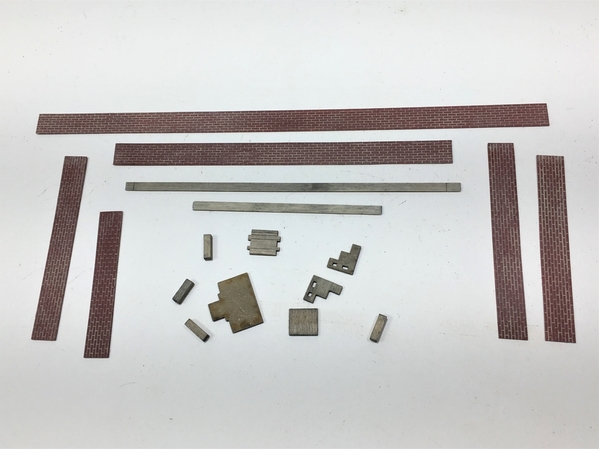

I worked on the model for about four hours on Saturday and made pretty good progress. First, I used Woodland Scenics acrylic “concrete” paint to make the mortar lines on the brick foundation strips. I had painted these “mineral red” about 12 days ago, so the paint was well cured. I applied a heavy coat of “concrete” paint to one strip at a time, let it dry for about a minute, and gently wiped away the excess paint with a paper towel. I should mention at the outset that the brick foundation is a modification. The kit instructions describe the foundation as being painted to look like concrete. I wanted an older look.

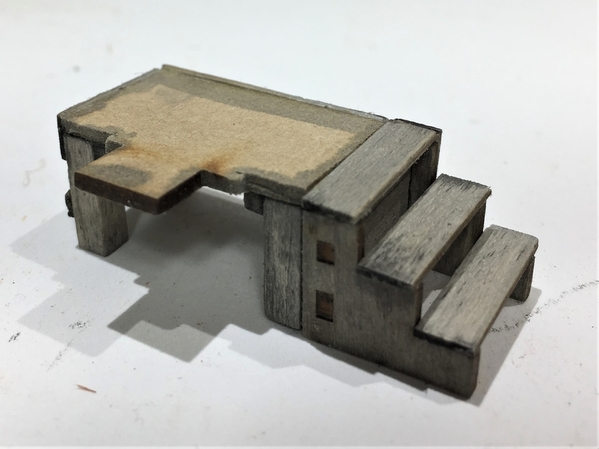

While the mortar paint was drying, I prepared the initial basswood pieces for the side-entry porch and stairs. This involved some accurate cutting and filing of the legs and stair treads, and checking to see that the parts would fit properly into the side doorway opening with the platform level when installed on the model. I then stained the pieces with a mixture of alcohol and India ink and assembled the stairs and porch separately, being careful to keep everything square and flat on the work surface. When the glue dried, I put the stairs and porch together. I also applied extra bracing on the underside of the porch to support the legs, and then added the external (horizontal) bracing.

Next, I drilled two holes in the floor through which the wires for the LEDs will pass.

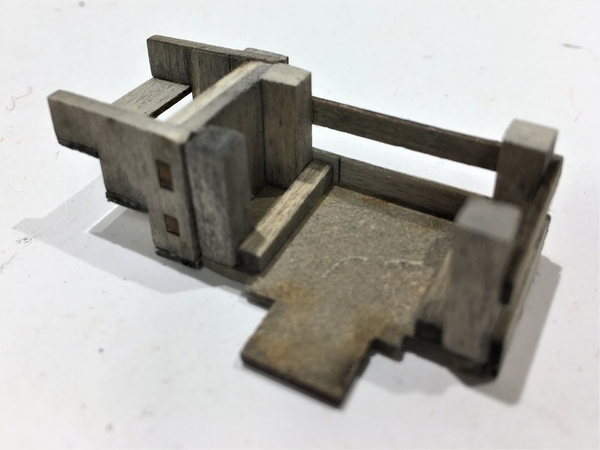

Before the porch could be attached to the building, I had to glue the brick foundation strips onto the sides and the rear. I trimmed each strip to the exact length required, with the two side strips overlapping the ends of the rear strip. I installed the rear strip first, using styrene plastic cement from a tube. This forms a very strong bond between the basswood at the base of the model and the plastic brick strip. While the cement was drying, I clamped the strips tightly against the basswood to get a strong bond.

The last picture in this sequence shows the brick foundation with the porch ready to be attached to the side of the building. The porch planking will be installed after the porch is in place.

Next steps will be:

1) Attach porch to building, complete flooring inside door, install porch planking

2) Paint and assemble doors, windows, glazing, frames and attach to model

Photos by:

MELGAR