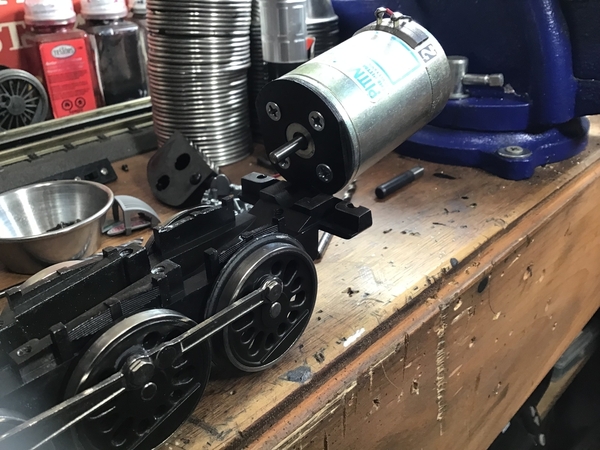

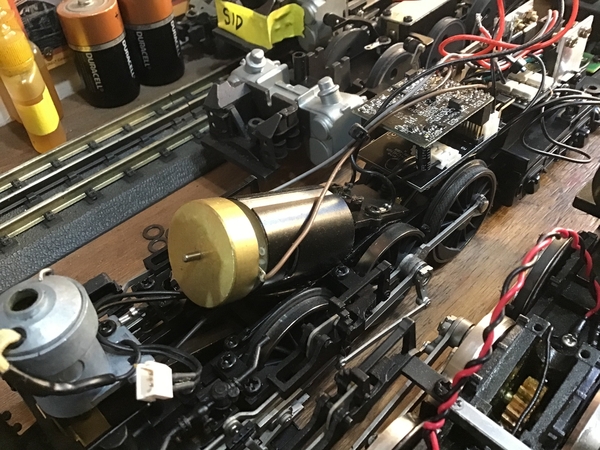

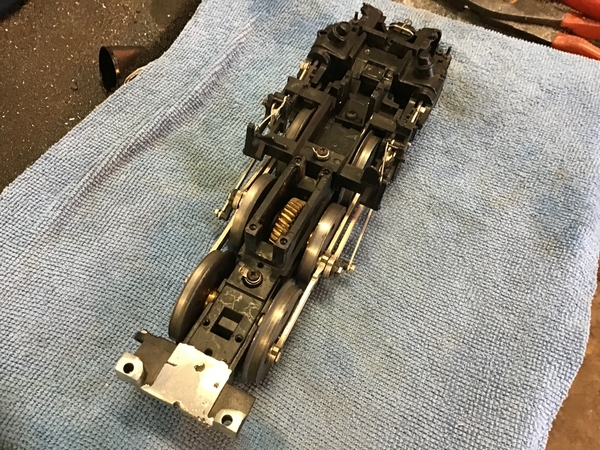

In my further attempt to level the playing field and get caught up, today’s task is to get as many Pulmor chassis swapped over to their new Pittman motors as possible….so today, we’ll venture out into the big shop to see what actually takes place, the tools I’ll use, the process to do the rough cuts, and the refinement to finally precision fit the Pittman…….Dennis’s 18056 (763) Hudson & Dave’s 18009 Mohawk are first up to bat,….naturally, we begin by stripping the Pulmor and all the electronics to prepare for cutting,….note as I take these locomotives apart, I’m looking at how well the chassis spins, back lash in the gear boxes, dried up nasty grease, and whatever else may need attention as we proceed for a smooth operating locomotive,……We need to cut off the Pulmor mount to make way for the Pittman, I’ve fabricated a sheet metal backer to protect the wheels as we begin the process,..

…..we start with a cut off tool ( buckeye) then proceed with roloc grinders, and carbide bit tools to erase the remains of the mount,…the pics you’re seeing are of all the rough initial cuts, we’ll refine these cuts and square everything up with files, belt sander, a good old fashioned square, and an angle finder to set the pitch we’ll need for the new motor mount,…..stay tuned, enjoy the pics, and the process, I’ll update hopefully throughout the weekend,…

…..we start with a cut off tool ( buckeye) then proceed with roloc grinders, and carbide bit tools to erase the remains of the mount,…the pics you’re seeing are of all the rough initial cuts, we’ll refine these cuts and square everything up with files, belt sander, a good old fashioned square, and an angle finder to set the pitch we’ll need for the new motor mount,…..stay tuned, enjoy the pics, and the process, I’ll update hopefully throughout the weekend,…

Pat