Afternoon gentlemen:

Sorry for my "silence", as life is getting in the way again, and I can't get to the layout as often as I would like.

Joe: Good to hear you could finally view my poor videoing skills.

Jon G.......what can I say.....

I followed your recommendations to the letter, yesterday afternoon (Wednesday), and still came up with the same results. No cigars for any of us!!!!

I place the loco on the track......turn the voltage on the Z4000 up to 12V (actually 11.5V on my multimeter at the track) and leave it there for 60 seconds to charge the BCR.

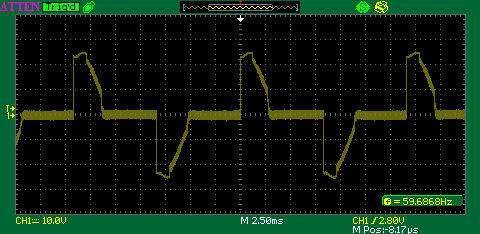

The moment I bring the throttle handle down to 9V on the Z4000 (with or without additional loads - lights etc) the voltage drops straight to zero, and I get 2 bell rings......no air line exhaust sound, no diesel engine idling sound....nothing. My multimeter confirms the drop in voltage (at the track) at the 9V mark to nothing, the moment the throttle handle continues to be lowered below 9V.

I bring the throttle lever back up to 9.5/10V, and sometimes I get the "clank" sound, telling me I am in the re-set mode, and to pick a feature I want to change. If I press the direction button at this stage for 2 seconds, while still at 9.5V, I get more "clinks and clanks", confirming the loco is definitely in the reset mode.

No amount of throttling up or down, or pressing of the direction button above or below 10V will alter the position of the circuit board to leave "re-set", and go to neutral, to get the loco to cycle to the forward position.

Next test:

I disconnect the Z4000 and re-connect the Z1000........hook-up my multimeter to the track again, and go through the same start-up process. My multimeter reads 10V at the track, and this equates to a small mark I have placed on the dial face of the transformer, to let me know where 10V is in relation to the pointer on the throttle, and the "orange stripes" MTH have printed on the transformer's fascia . The bottom "stripe" on the fascia equates to 2.5V, before the transformer shuts down to zero volts.

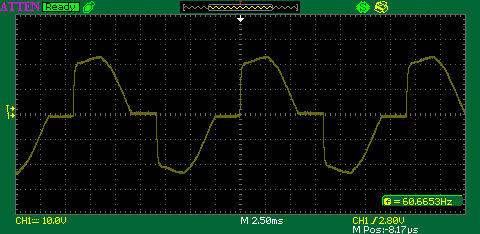

Place the same loco on the track, go through the same start-up procedure for charging the BCR, slowly lower the throttle to just above 2V, and I get the air line release sound. Raise the throttle within 2 seconds, and the loco starts to move at around 5V. As I continue raising the throttle, the loco goes faster, and the diesel engine sound increases under the load, to a point when I have about 7V - 8V going to the track.

With the loco running at around 8V (good freight train speed) I hit the direction button (and release it), and it comes to a steady stop in neutral. Hit and release the direction button again, and it slowly moves off in reverse till it is up and running at the same speed.....nothing unusual here!!!

What I have noticed on the Z1000 is I cannot get the loco to leave the "re-set" mode at the initial start-up (after charging the BCR) if I just hit the direction button while the voltage is still at 10V. It tries to go into the "select a feature" re-set mode, and I have to literally lower the throttle handle to about 2V to trigger the board, and then everything is working again. These loco's will not respond to just pushing the direction button at the initial start-up phase.....I must lower the throttle manually to 2V, and then back up again, to get them to move forward.

SUMMARY: It seems to me that these three PS1 diesels, and one PS1 steamer are super sensitive, and require a constant and steady lowering of the voltage to about 2V to get them to cycle properly.

What I intend to do in the next day or so (life permitting) is to do a video on my phone of the start-up process using the Z4000, and have audio as well, so you can here the "clinks & clanks", the 2 bell rings, the lack of air pressure release, and the muted diesel engine sounds as I raise and lower the throttle, and hit the direction button. I am hoping this will give you guys an idea of what is happening when I use the Z4000 to power the track.

As before......stay tuned, cause there is more to come......the fat lady is not singing yet!!!

Peter.....(Buco Australia)