Thank you! I have those paints also, but didn't have anything in the grays (or even black), but had a nice mix of the tube acrylics. I should use them since they don't last forever either. I did tone down the stone work by getting rid of the blackest color and paint it carefully with Tamiya Neutral Grey. I still want to overspray some light gray (just a dusting) to further subdue the harshness. I used a small brush and re-did some of the mortar lines as well.

I went around with another mix of brick red and put a second coat on all the window packing since I had completely missed one part yesterday and the rest weren't covered well enough. I lightened up the mix just a bit to improve the match with the Plastruct brick color.

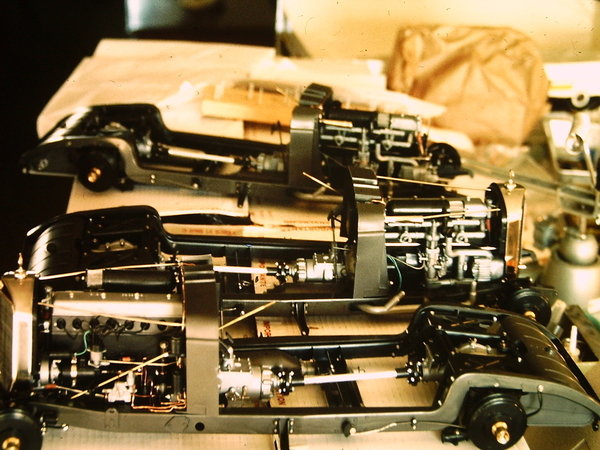

It was time to start building the interior. As I noted, this all has to be done and in place before the ceiling goes in. I had three ways to fabricate the interior: 1/8" Masonite, thin Foamcore, or built up with styrene. Masonite is not so easy to cut and shape, Foamcore is not very stable especially in cross-section, which left using styrene.

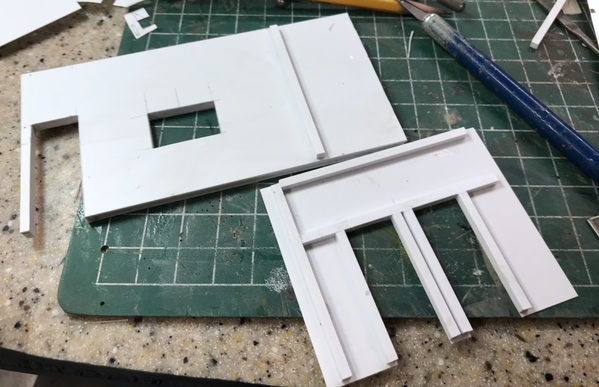

I built the walls sort of replicating how real partitions are built using thin surface material supported internally with some framing. For the framing I used 1/8" square Evergreen stock. I laid out the door and pass through locations and glued the framing up to these lines. Then I cut the opening out with one side's facing in place.

I used Testor's tube cement again to give me a little more positioning time. The solvent cement sets so fast that you often can't get the piece down before it's already kicked. The sheathing is 0.020" styrene. I then applied glue to the frame and attached the second side sheet. I then cut its openings through the other side.

To attach the walls at right angles I pre-glued the square stock at the location on the through wall and left space in the sheeting before the frame piece so the two walls keyed together.

For the last turn I simply used a single thickness of 0.040" sheeting since this didn't need any thickness. Actually, none of the walls really need to be scale thickness except at the pass through to the kitchen which I could have simulated with just some thickening pieces right at the window. But, I makes me feel better to make them like real walls.

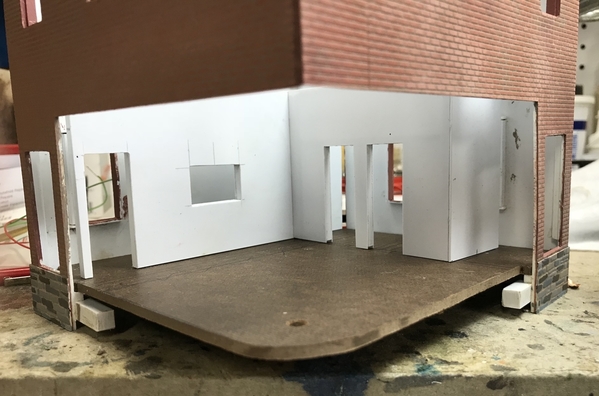

I test fit the walls in place. The front and back doors don't align well, but it doesn't matter since I'm no longer using that door. It will be covered by the exterior stair housing that I added to the design later when I came to the conclusion that there really wasn't enough room for an actual staircase in the building's confines.

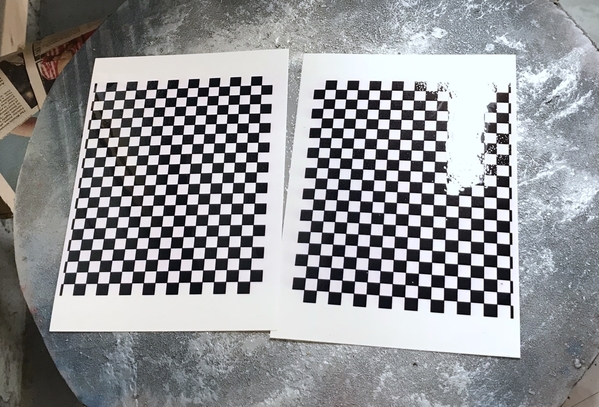

I needed to think about the flooring before I went any further. The flooring needs to be added to the floor piece when it's outside of the building before gluing it in. I already had a good black and white checkered floor pattern that I used in the Distillery Boiler House, and put it to use again here. Actually, I designed this when building Saulena's tavern 11 years ago. I printed it out of 5 X 7 photo paper, and after dry, sprayed it with Grumbacher Final Fixative to preserve the inkjet ink.]

I tried the walls on the flooring. BTW: made two sets just in case I screw one up. One is sufficient to cover the space.

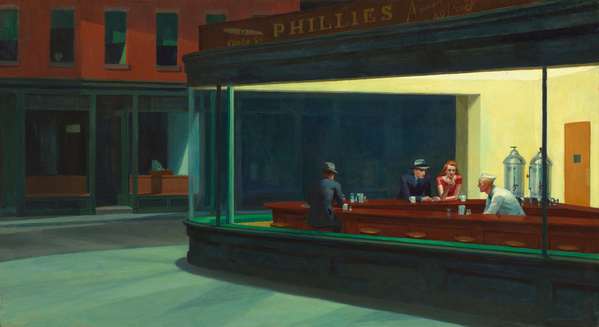

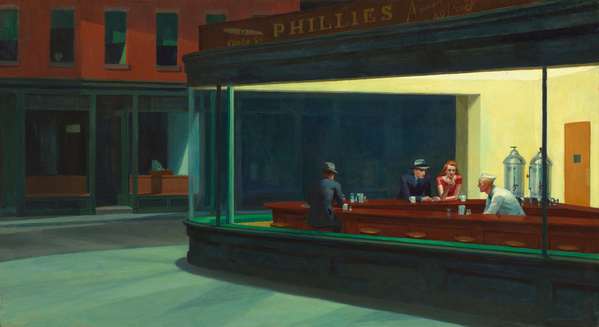

I made a wooden pass through sill and also pre-stained more wood strips for the door, window and baseboards. I noticed in Hopper's painting that the door has no frame at all. It's just an orange rectangle. I'm conflicted about how close to the painting I should be. On one hand, I'm trying to replicate the painting in 3D, but I've already deviated from the painting by making the counter rectangular, not a triangle like Hopper drew. The painting doesn't show a pass through since the wall is cut off before it would show. I did drill the hole for the support pole by clamping the ceiling and floor pieces together so the holes are in line. I have to make a ton of bar stools. Anyone know if there are any pre-built ones out there? I'm not sure where that door actually goes. Notice also the wall thickness next to the red head. It looks well over a scale foot with the glass bisecting it. My wall will not be that thick. It will be about a scale foot. (or less). According to the story, Hopper was painting a cafe that more or less existed in NYC. I will match that yellow and green as best as I can. It's a very well lit space and mine will be also. And I'm going to have sculpt the figures. John Armstrong did it, so I should be able to also. Heh…heh…!