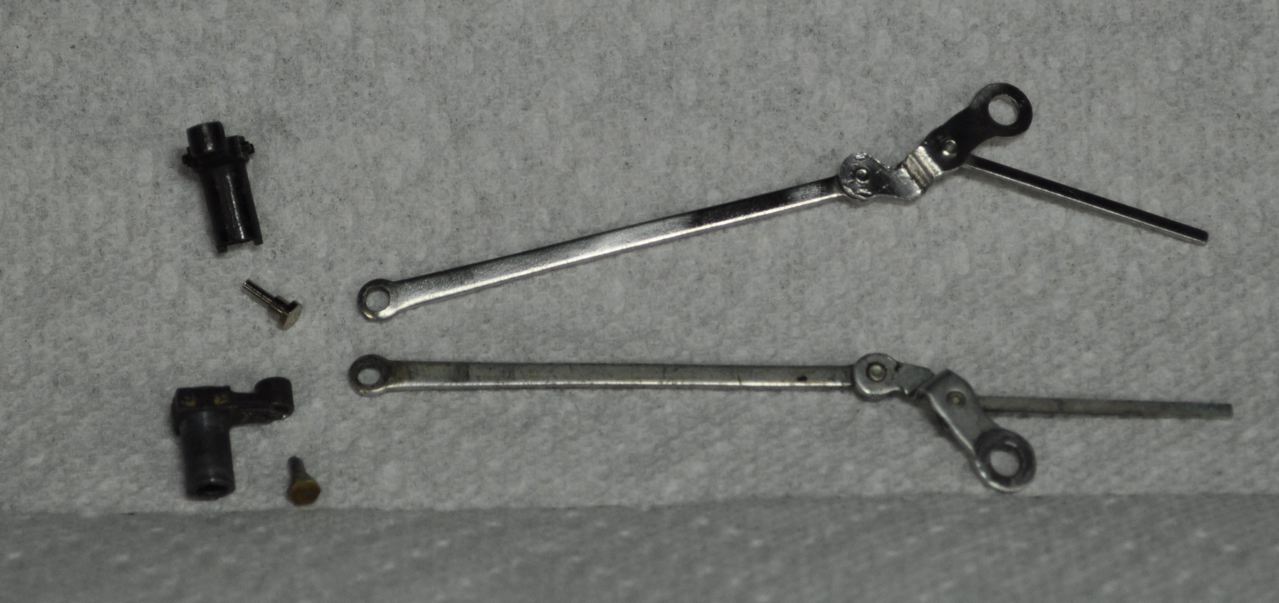

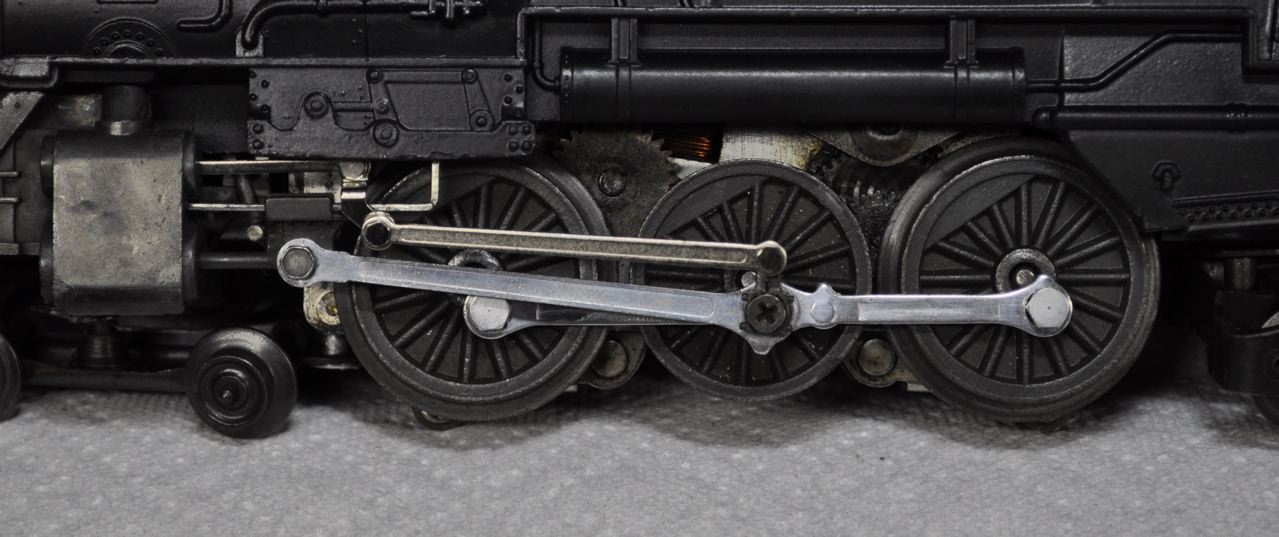

IMHO...it will be impossible to completely clean the drive/side rods on the engine without removing them. Any tool, compound, etc., will not clean the rod surfaces immediately adjacent to the hub screws. Also, you'll run the risk of damaging adjacent components/areas of your engine in trying to clean the attached rods. Just sayin'.

The tool I use is from Micro-Mark...

Brush Link

They also sell a near-identical version with brass or steel bristles, but this fiberglass version, while aggressive to oxidation/dirt, imparts far less noticeable scratch marks. But, here again is a reason to remove the rods...you will not want any fine particles of fiberglass to remain on any oily/greasy surfaces of the engine for obvious reasons. (Like a pencil eraser, this brush will attrit through use.) Ergo, clean the rods lying on a disposable paper towel or rag on the workbench surface. Then dispose of the towel/rag when done.

BTW...I use the same brush for cleaning accessible electrical contacts...but NOT motor commutators unless they can be washed afterwards! (i.e., the armature is removeable.) Also, if you should order the M/M brush, I recommend also ordering a packet of replacement brush refills.

OTOH, TEHO. This is just a suggestion from my own experience....FWIW.

KD