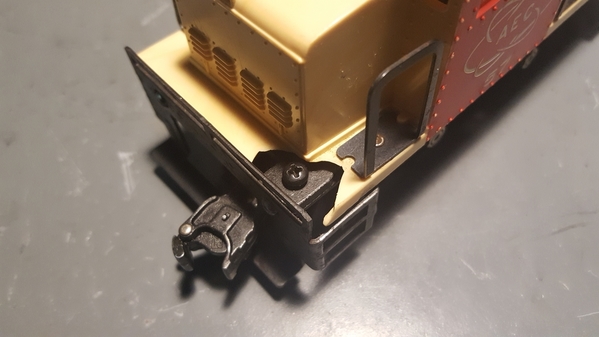

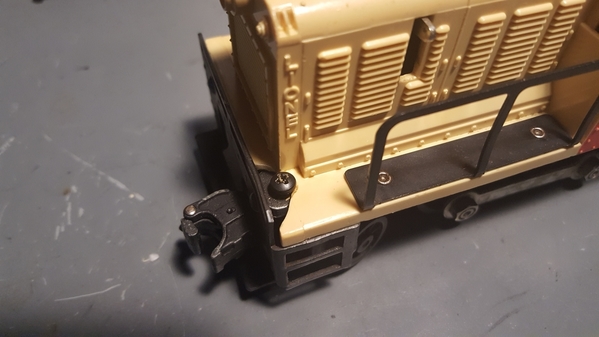

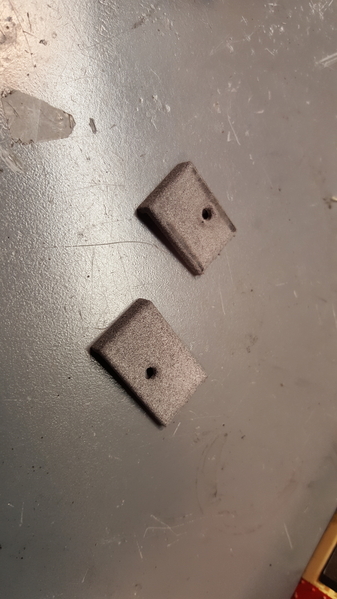

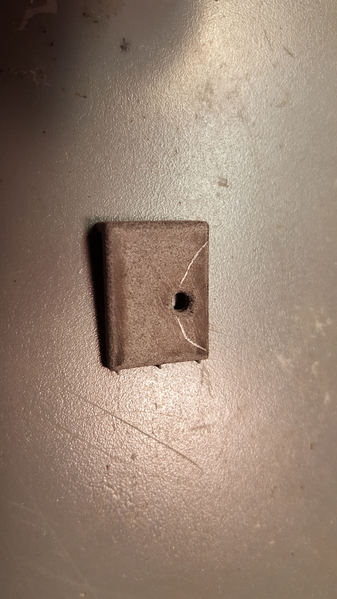

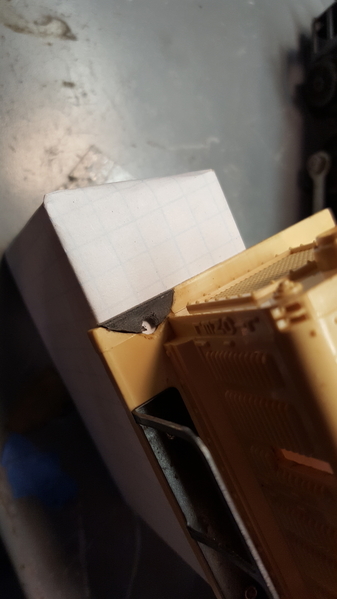

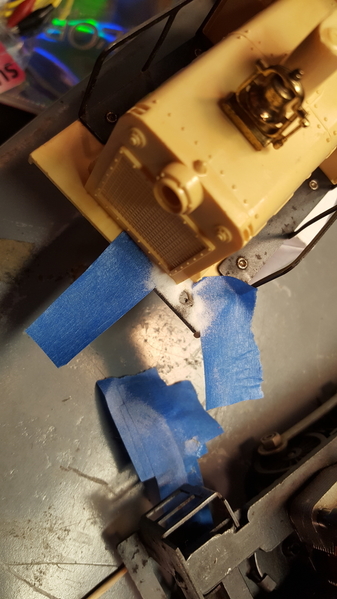

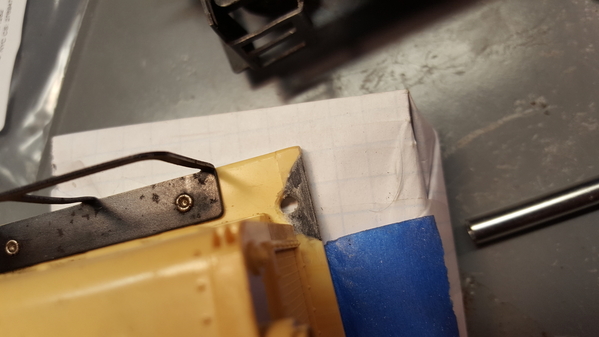

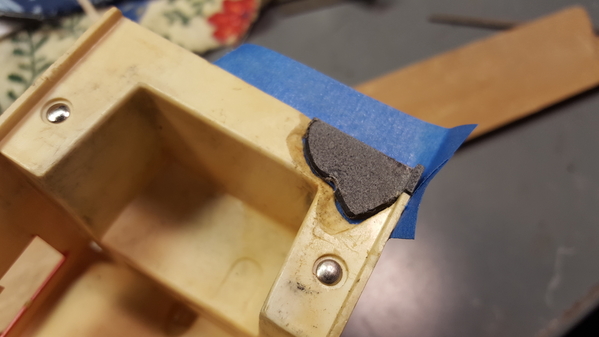

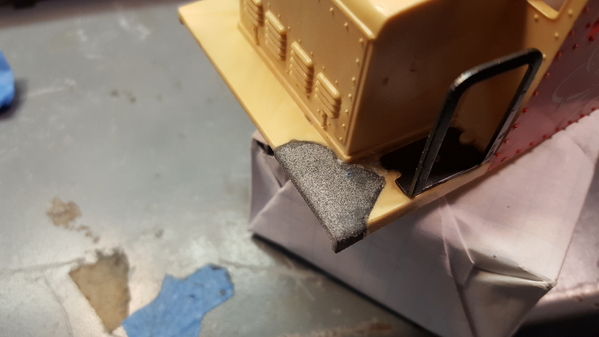

Has anyone repaired or rebuilt the shells of the 2-4-2 Vulcan switcher? I have one suffering from the usual missing or cracked corner where the screw hole is located. In my situation a large chunk of both corners is missing to the point where no screw hole remains.

Options I'm considering are casting epoxy or JB Weld in place or 3D printing the missing geometry.

Ill try and add photos when I can.

Thanks