I acquire a basket case Lobaugh Berkshire. Since this kit was produce more that 70 years ago it has never been completed. Many owners have done awful things to it. It was covered in enough solder to build a dozen locomotives. Later someone tried to epoxy the tender together with predicable results (It was applied with the philosophy that If too much epoxy didn’t work more should do the trick). Half inch-thick blobs of solder and epoxy were used to attach the air tanks and the feed water heater. The mechanism could not rotate a full revolution and after examining the gear box (no gear wear) this locomotive has never run. Add thick grease and grime on every surface and missing parts and we’re got a very challenging restoration project.

The first thing to do was disassemble everything. Each part had to have solder and epoxy removed and then a thorough cleaning

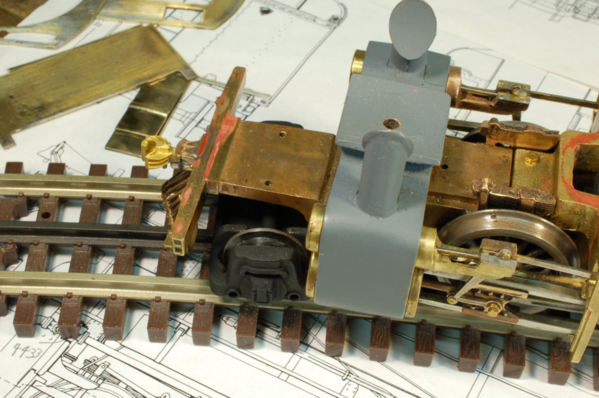

The first step was to blind the center drivers and make new steel tires for the first and 4th axel. There were many issues to resolve (driver quartering, crank pins that were too short, axel slots too tight, and crank pin covers that took the play between the crank pins and the side rods). The photo below shows the reassembled mechanism with the new tire on the first axel.

The cylinders are already primed. Someone had ground the sides of the cylinders down below the level of the cylinder caps to remove voids in the casting. Bondo was used to add the thickness back to its correct level. 0.005 soft sheet brass was glued over the Bondo and then the cylinders were primed.

The engine had been dropped at some point and the pilot was cracked. A new precision scale pilot soldered in its place

The original motor was a universal motor and wanted a DC motor. I used an old 9000 series Pittman I bought on Ebay

The front and rear trucks were rebuilt with new 3 rail wheelsets. Some of the sand casting had "soft" details. They were cleaned up and additions details were added.

The mechanism has been bench tested and rotates smoothly now (This was a lot of work). Below the mechanism is shown on a section of 072 track. The only significant modification was to move the front truck pivot point forward 1/8" to clear the cylinders. I also had to move the new pilot forward 1/8" to accommodate the truck. I don't feel that this is a compromise since the drawing of this locomotive in MR show that the distance from the cylinder front to the pilot was nearly 1/8" short on the model.

That's it for now. I will start on the boiler and cab next