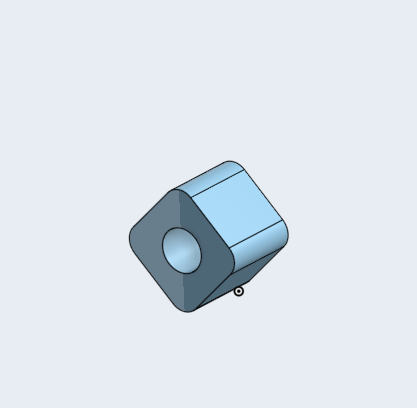

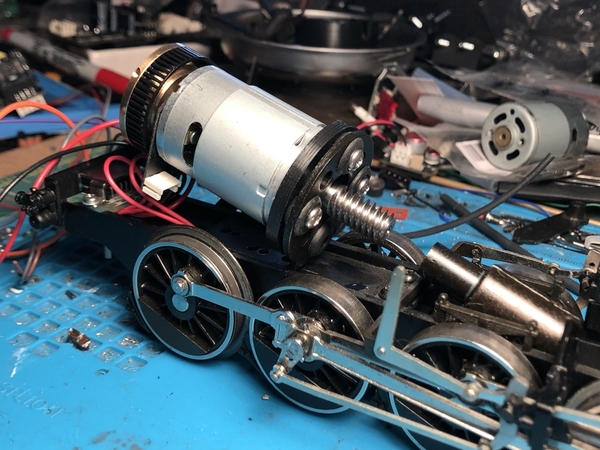

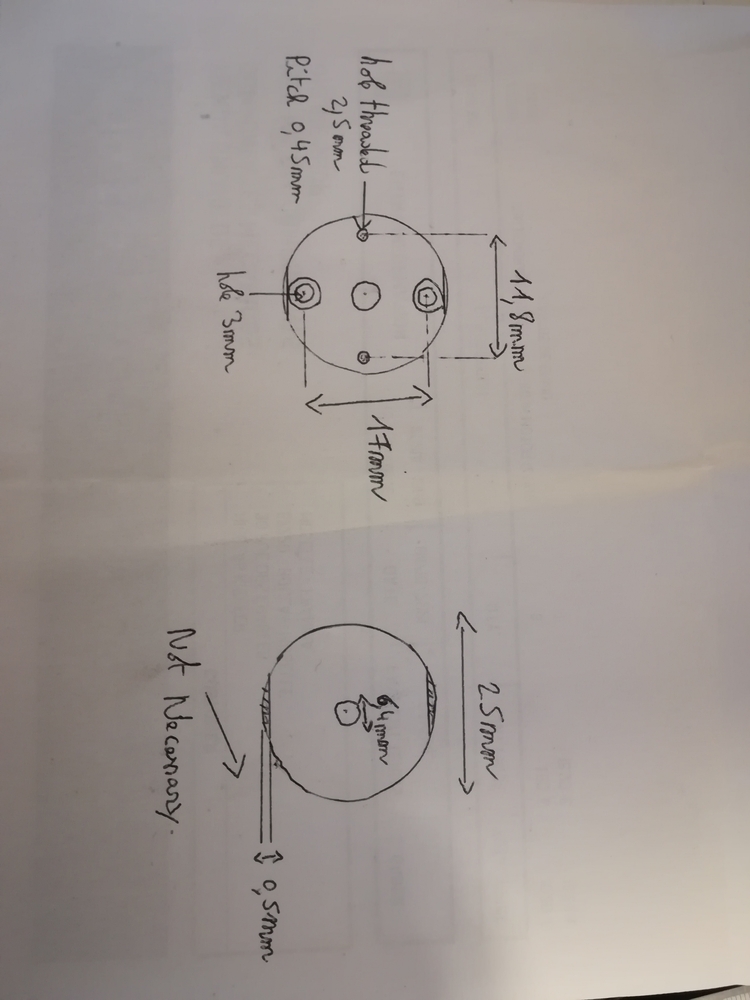

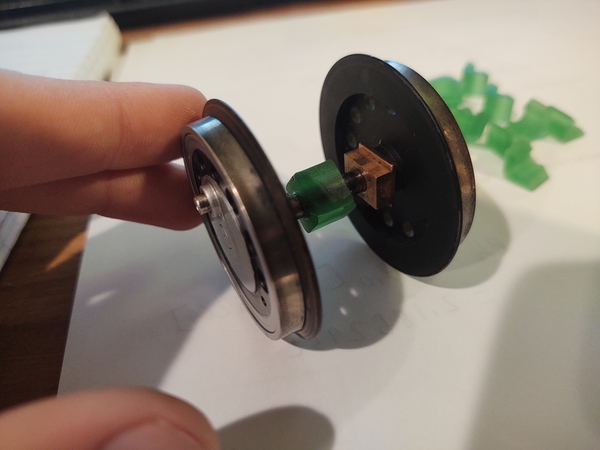

I have finally gotten around to getting my first 3D FDM printer, a Creality Ender 3 Pro. I really wanted to create simple parts, mostly adapter plates and other items that would be mostly used for my engine and rolling stock projects. Things like Kadee adapters, pickup roller mounts, etc. that would help make my projects more consistent. One item I thought would be useful in the future would be an axle mounted magnetic chuff generator. I built this one in two halves and made it so I could embed perfectly spaced 3mm magnets that a reed switch could pick up for chuff input to my RS boards. This was made for a 4mm axle but could be easily adjusted for any size. The outer diameter could be adjusted for internal clearance or to aid the reed switch pickup. This was meant for a locomotive axle so I can get 4 chuffs synched to crosshead/crankpin position (I am obsessed sorry) but could be also used on a tender axle by only populating two spots 180 degrees out. On an axle with a lot of lateral slop, the width of the cam could be adjusted and the magnet inserts could be changed to host square or rectangular mini magnets.

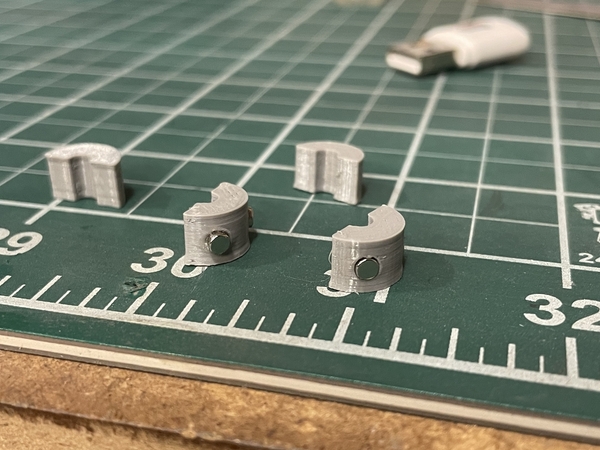

I was very anxious to try this little project as I thought it would be a great way to break in my new printer. I doodled up the design in Tinkercad and used the Creality slicer software to make the gcode. I had a few rough shots before playing with the bed height, nozzle temp and brim support. The bed height and brim support helped get the Z axis height correct. If you notice the first attempts were kinda squashed (middle pic). I also embedded the magnets a bit deeper in Tinkercad. If anyone's interested, I can put up the .stl file or share it on Tinkercad.

Youtube tutorials on Tinkercad modeling and the Ender setup were of immense help.

I am almost overjoyed with the possibilities. I have another 3RS brass steam project on deck (another 3rd Rail Q2 has found its way to me) so I will definitely be using this quite a bit in the near future.