HERE are 27 products that looked great but flopped.

In twenty years, 3D printing has not made the list.

1) McDonald’s Arch Deluxe

I still remember commercials on TV for the Arch Deluxe which began airing in 1996 but no amount of advertising could save this burger. It was an attempt to offer “upscale” product offerings but customers weren’t lovin’ it.

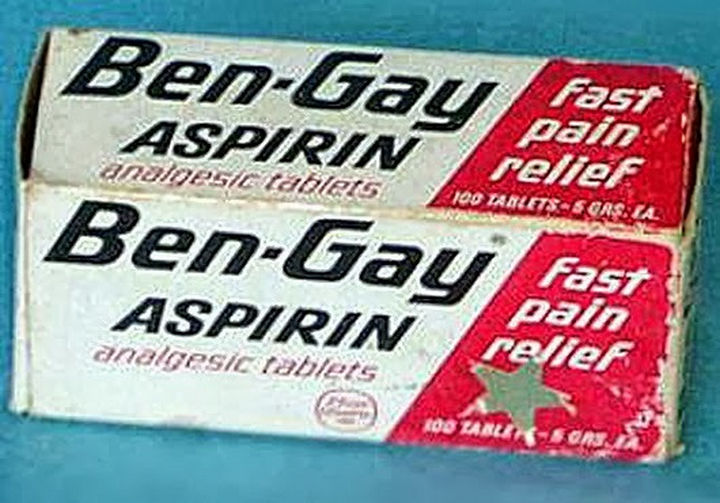

2) Ben-Gay Aspirin

Ben-Gay is a strong brand because when you hear the word “Ben-Gay”, you immediately think of pain relief cream. But that is the problem and the main reason why this aspirin product never lasted. People just didn’t like the thought of swallowing anything relating to Ben-Gay.

3) Bic Underwear

Bic is a company that is well-known for its line of disposable razors, lighters, and pens. When the company released underwear, most consumers didn’t understand why and passed.

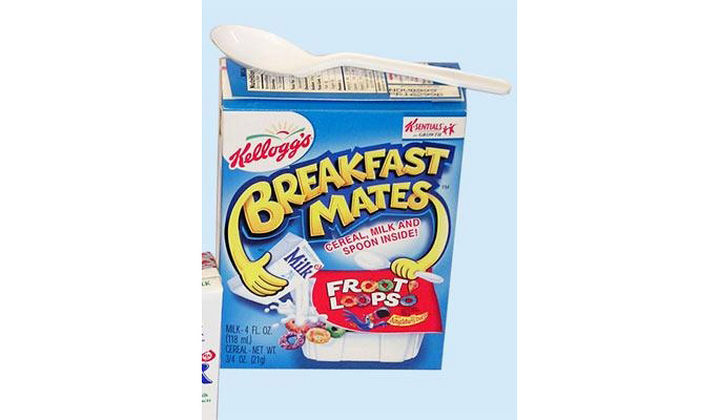

4) Kellogg’s Breakfast Mates

More failed products that probably looked good on paper but kids just didn’t understand the packaging or its instructions. Opening a box of cereal and pouring cold fresh milk in a bowl is so much easier and Kellogg’s later realized this.

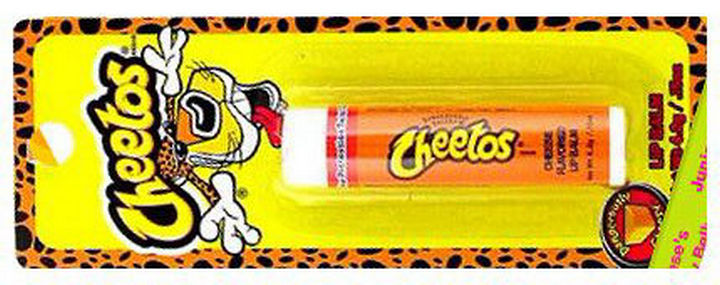

5) Cheetos Lip Balm

If you love licking your fingers after eating Cheetos, you would think this product would be great. Unfortunately, it apparently didn’t even taste like Cheetos.

6) Colgate Frozen Kitchen Entrees

Colgate may be one of the leading toothpaste brands but consumers just couldn’t comprehend buying Colgate “food”. I suppose Colgate thought that by eating a Colgate meal, people would then brush afterwards with Colgate toothpaste but it was a bad idea from the start.

7) Coors Rocky Mountain Water

While soft drink companies are successfully selling water under different brands, Coors just couldn’t do the same with it’s rocky mountain water. When consumers buy Coors water, they expect it to be fermented with barley, hops, and yeast.

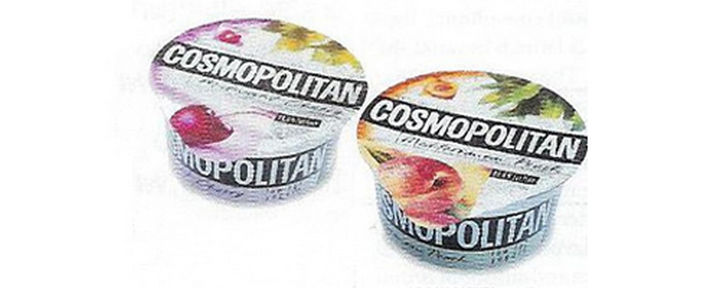

8) Cosmopolitan Yogurt

Sure, yogurt is a growing product category but when you’re a company that publishes 58 editions and distributes them to more than 100 countries, then Cosmopolitan should stick to what it does best. They did try to sell their own brand of yogurt but lackluster sales caused them to pull their failed products off shelves after only 18 months.

9) Crystal Pepsi

In the 90’s, people were were obsessed with clear products. Clear soap, see-through phones, and transparent soft drinks. Pepsi jumped onto the bandwagon by offering Crystal Pepsi but it didn’t last long.

10) Microsoft Bob

Source Unknown

Bob’s your uncle or so Microsoft thought. Bob was released who found Windows 95 intimidating since so many new customers were purchasing computers for the first in the mid-90’s because of this this thing called the “Internet” that started getting popular around 1995. Bob was supposed to help with simple tasks but it only made things more complicated so Microsoft didn’t create future versions of the software.

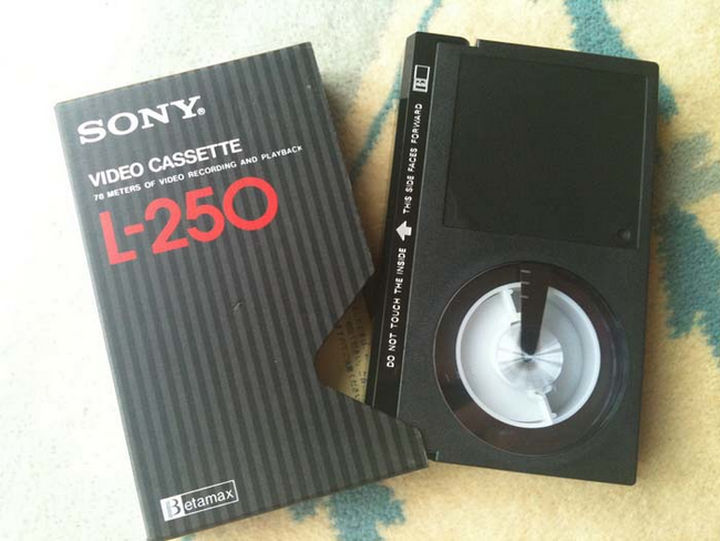

11) Sony’s Betamax

Sony may have been first to market with its Betamax in 1975, but the format wars began when JVC and Matsu****a released the VHS format and video player two years later in 1977. Because VHS was a licensed standard, any company could produce video players which drove costs down but because Sony didn’t license the Betamax format, its players remained expensive.

12) Ford Edsel

Ford has had a lot of success in its 100+ year history but the Ford Edsel wasn’t a model they could call a winner. It was called the “Titanic of Automobiles” and had disappointing sales. When Ford released the Mustang in 1964, it was a huge success and anybody that still had a bad taste in their mouth about the Edsel quickly forgot about it after driving a Mustang.

13) Gerber Singles

Back in 1974, Gerber wanted to expand their line of pureed meats, vegetables, and fruits to college kids or people that were living alone for the first time. Nothing makes you feel more like an adult than eating meat mush out of a baby food jar with a spoon. Needless to say, their failed products didn’t last long on the market.

14) Harley Davidson Perfume

I know what you’re thinking. What man doesn’t want to smell like a ‘Hot Road’? It’s understandable that Harley-Davidson owners want to own everything the company makes because the brand is legendary but loyal customers had to draw the line somewhere.

15) Heinz EZ Squirt Ketchup

Ketchup is a difficult product to expand because customers are already happy with Heinz ketchup. There is only so many ways to improve ketchup but Heinz thought one way to expand the product line was by creating “mystery colors”. While kids may have enjoyed its grossness factor, it wasn’t enough for Heinz to keep it in their product line.

16) HP TouchPad

Failed products like this tablet from HP was far from being the “iPad killer” some tech magazines and websites were claiming it to be. It was based on a new operating system called webOS and had virtually no third-party support which is why retailers quickly had a fire sale to get rid of it as quickly as possible.

17) Earring Magic Ken

When Mattel decided to release a hipper version of Ken in 1993 featuring a mesh t-shirt, lavender vest, and one earring, it didn’t expect to get so much backlash. It drew criticism from the gay community for proposing false stereotypes and Mattel stopped production of the doll.

18) Life Savers Soft Drinks

Life Savers may be one of Wrigley’s most successful products and the number one brand of non-chocolate candy but as a soft drink, it tanked. Drinking liquid candy just didn’t win over consumers.

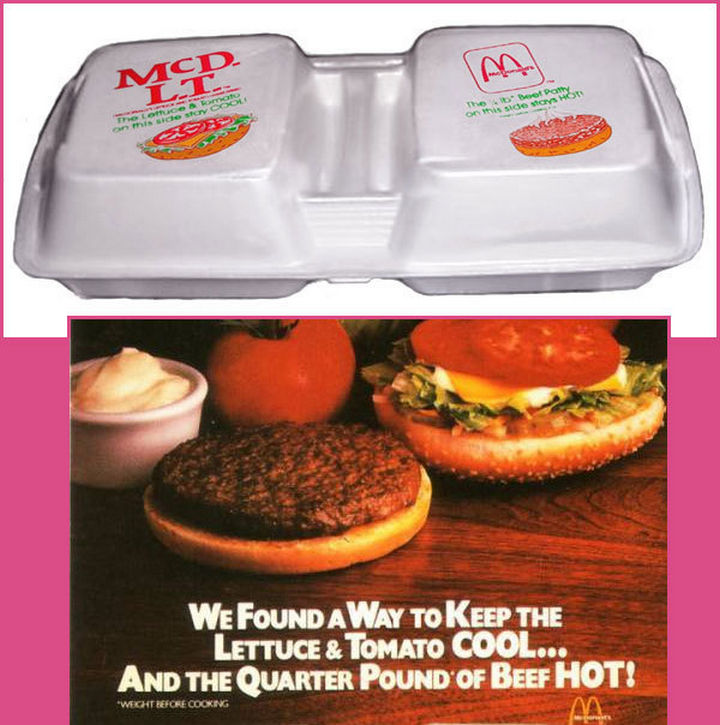

19) McDonald’s McDLT

Nobody likes soggy burgers so McDonald’s figured that if they could provide a burger that separated the cold condiments and veggies from the hot beef patty, they’d have a winner. It didn’t last long and it partly was because customers did not like having to assemble their burgers and making a mess.

20) Microsoft Zune

Microsoft released the Zune almost five years after the original iPod and couldn’t make a dent in Apple’s 65% market share in personal audio players. It was discontinued in 2011 and Microsoft encouraged users to purchase a Windows phone instead but that strategy doesn’t seem to be working either.

21) New Coke

When Coca-Cola released the “New Coke” in 1985, executives could probably hear their loyal customers around the world weeping every time they took a sip. After boycotts and protests, Coca-Cola quickly reintroduced the original Coke as “Coke Classic”.

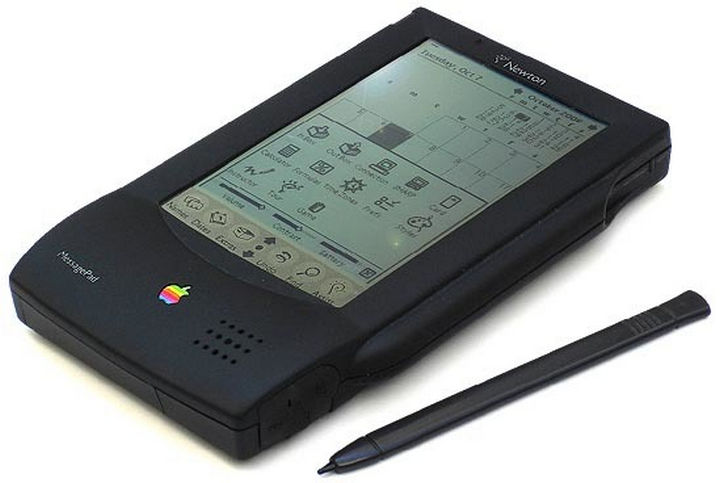

22) Apple Newton

The Apple Newton was ahead of its time and had great features but the only problem was, most of the features didn’t work properly such as writing recognition. The product may have initially flopped but it paved the way for the Palm Pilot, BlackBerry, and eventually the iPhone (ditched the stylus!)

23) Pepsi A.M.

Cola soft drinks have caffeine and so does coffee right? Pepsi thought they could no wrong by offering a soft drink you can drink in the morning but most consumers didn’t want to drink soft drinks morning, noon, and night.

24) The Segway

The Segway is another great example of failed products that received tons of hype in the press but failed miserably when they were actually released. The company expected to sell anywhere from 50,000 to 100,000 units in its first year but it took them over two years to sell a meager 23,500 units.

25) RJ Reynolds’ Smokeless Cigarettes

These came out in 1988 and apparently “produced a smell and a flavor that left users retching”. Sounds great already! Besides the fact that they tasted horrible, rumors began circulating that they were being used by some customers as a delivery device for crack cocaine. The company quickly pulled them off the shelves.

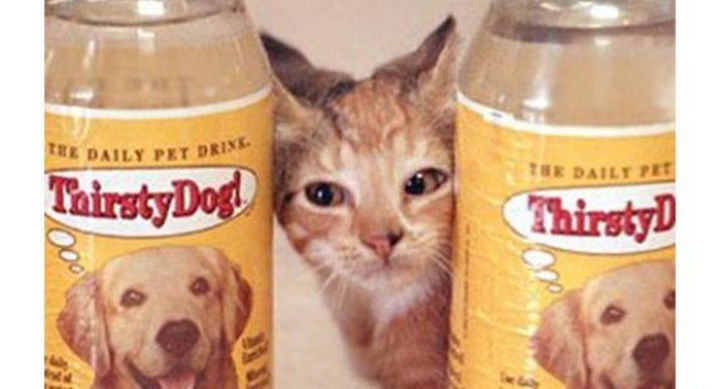

26) Thirsty Cat! and Thirsty Dog! bottled water

In what could be considered a soft drink for pets, this daily pet drink had great flavors like Tasty Beef and Tangy Fish. While pets probably enjoyed it, pet owners didn’t see a need for feeding the pets with sugar water.

27) WOW! snack foods

Olestra is a fat substitute that was approved by the FDA in 1996 and still approved to this day. These chips may cause stomach upset, cramps, gas, and loose bowels but they’re fat free! All kidding aside, consumers just weren’t ready for snack foods with a health disclaimer on every package.

NOTHING ABOUT 3D printers.