Replies sorted oldest to newest

Charlie, I think its a great idea to attempt to build an operating turntable, however, for what its worth, I would buy a Millhouse TT, with TMCC Control. You, in the long run would be $$$$ ahead. If you plan on running a Big Boy, or a small Switch Engine, the Millhouse TT runs smooth and is going to be a Real Focal Point of Interest on Your Railroad. The new MTH Engines, and the New Lionel Engines are fun to run and if you are trying to save money making your own turntable, this is why I recommend getting a precision made TT. Do not be mad at me, this is just what I would do. Good Luck, and Happy Railroading

Turntable project slideshow. Have fun with your project![]() . Click on the underlined phrase to link.

. Click on the underlined phrase to link.

Parts list.

Mike,

I just looked at your build pictures. How many hours do you estimate it took to build?

Love your work, you're one of the truly talented modelers on the forum.

Mike,

I just looked at your build pictures. How many hours do you estimate it took to build?

I didn't keep track of the hours. Material cost for the TT was over $1,200

Love your work, you're one of the truly talented modelers on the forum.

Thank you ![]()

Turntable project slideshow. Have fun with your project![]() . Click on the underlined phrase to link.

. Click on the underlined phrase to link.

That's quite a lot more turntable than I might consider as well as one that's also far more modern than I am considering. I'm looking more for a far earlier one not unlike a gallows style turntable that would service a more rural turn of the century line.

I used a Diamond Scale tt years ago on a now dismantled layout.

If you want to build one, go for it. But, I'm reminded of the work I put into having a '65 Mustang repainted by a buddy and all the prep work I put into it. My brother had his '65 Mustang repainted by a good body shop.

My paint job was crap compared to his. And the body shop owner, who I knew, told me I should have spent the many hours prepping the car for a bad paint job by flipping burghers and using the money I earned to pay a pro for a good job--that advice has always stuck with me.

Turntable project slideshow. Have fun with your project![]() . Click on the underlined phrase to link.

. Click on the underlined phrase to link.

That's quite a lot more turntable than I might consider as well as one that's also far more modern than I am considering. I'm looking more for a far earlier one not unlike a gallows style turntable that would service a more rural turn of the century line.

Diamond Scale had done a gallows turntable in HO but not O. Contact me via my e-mail Martin I have a lot of Diamond Scale parts.

Hi Charlie,

You can run our turntables with the MTH remote but it would still have to use TMCC like you can with TMCC engines. Problem is that MTH's software isn't open source. That is why manufactures use TMCC since it is open source. If you decide to not build your own take a look at our tables and index system. very flexible to configure to your track plan. Take care.

(1.)We have used this Turntable for the Fort Pitt Highrailer layout since it was made 2007. We did an upgrade to DCS a few years ago for the whole layout. The TT and RH (Round House) modules, as wired, worked with DCS, but it required a separate TIU for these modules because of the 13 plus engines. It requires (2) PH 180 Lionel Transformers in Parallel to power these two modules, separate from the rest of the modular display.

(2.) In rush current, on start-up, of 13+ engines, at one time, is the reason for the parallel power.

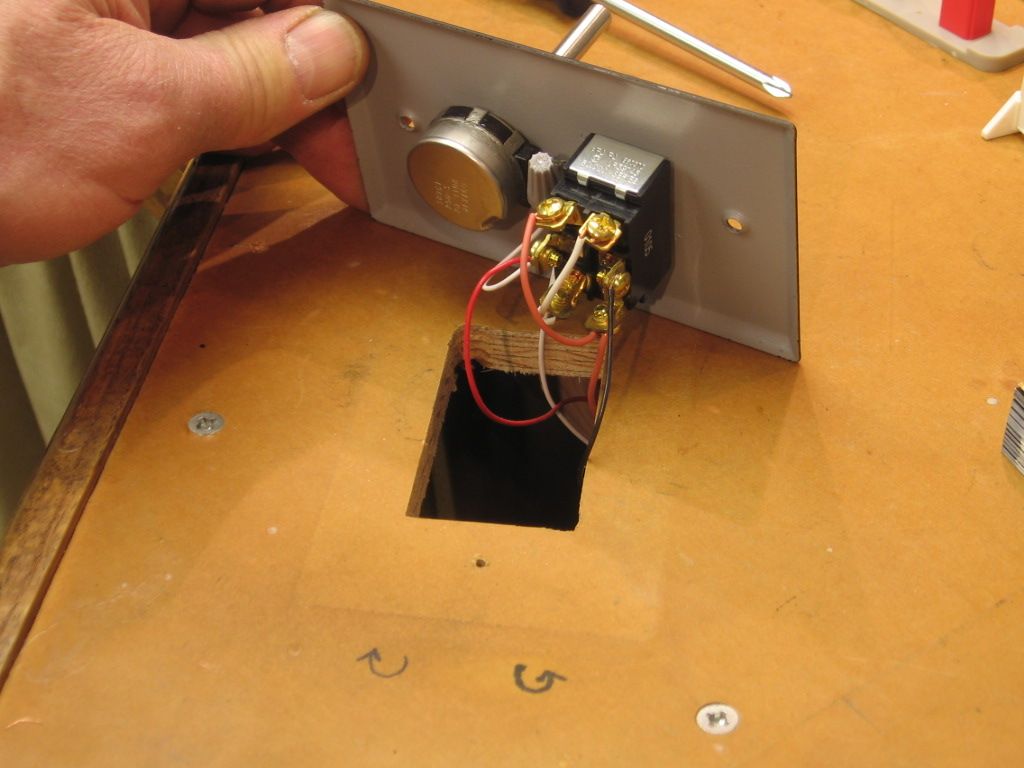

(3.) Control of the small 12 volt DC motor is with (2) momentary, center off, momentary Double pole cross over switches. Switch location is either side of the TT.

(4.)There is also a small variable resistor to vary voltage/speed of the turntable drive.

(5.)Track alignment is done by sight. Site alignment is done using the switch to jog the bridge to final position.

(6.)The bridge is removed from the pit, boxed, and shipped separately when used. Two screws and the bridge is out.

Bridge ready to ship.

Y-module and TT.

And the Korber house adds to it.

Power supply

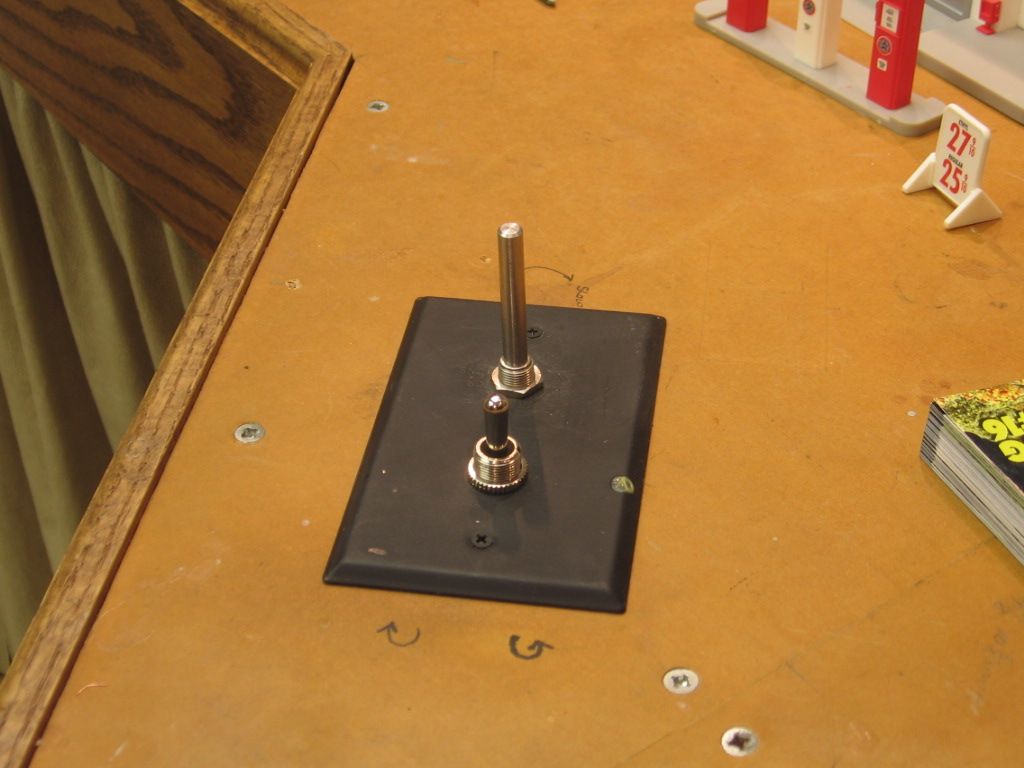

Control, clockwise/counter-clockwise, and variable speed bottom of picture. Similar switch and variable control on my layout Diamond Scale TT.

I used a Diamond Scale tt years ago on a now dismantled layout.

If you want to build one, go for it. But, I'm reminded of the work I put into having a '65 Mustang repainted by a buddy and all the prep work I put into it. My brother had his '65 Mustang repainted by a good body shop.

My paint job was crap compared to his. And the body shop owner, who I knew, told me I should have spent the many hours prepping the car for a bad paint job by flipping burghers and using the money I earned to pay a pro for a good job--that advice has always stuck with me.

That's why I stay away from kits. When I looked at the one we wanted to add to the layout, with its "thousands" pieces in the box, I gave it to a model builder. Cost a pretty penny way more than the kit alone, but came back looking better than I could have done. Mine would have been the crap paint job.

(Think Dagwood's woodworking creations from his workshop.)

Charlie, if you want to go into the business of supplying TT's, just build one that is compatible with the various operating systems.

I thought that was his intent from the original post.