Hello--

Just set up the 3-weeks-per-year Xmas tree layout, and I am having a strange issue with my 6557 caboose that I haven't encountered before.

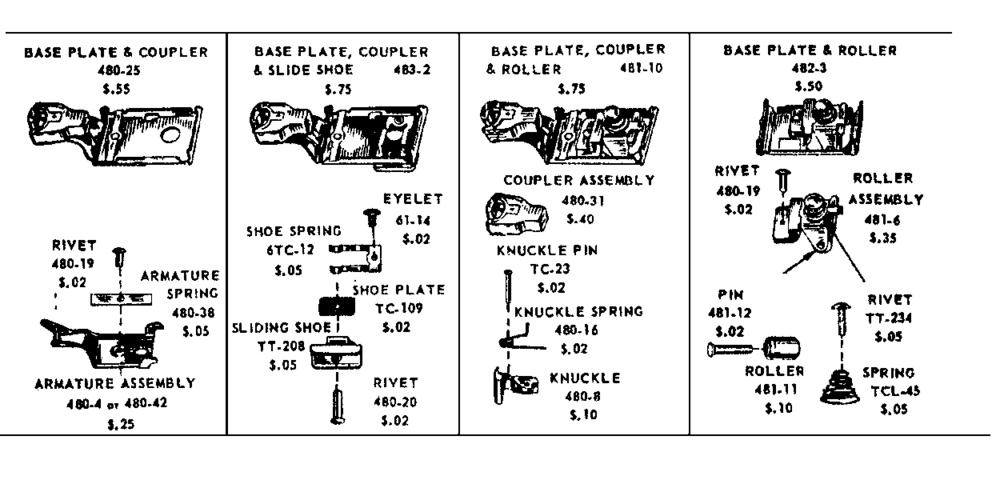

Upon pushing together the two plywood sheets that form the large O-gauge oval, I used the special track "eraser" as I always do to clean most of the oxidation off the tracks after sitting since last January. After hooking up the ZW transformer, I fired 'em up. Within two passes around the oval, I noted the 6557 was no longer lighting up...uh oh. I took it apart to inspect it, and the solder connections and bulb were all ok. The problem? The contact roller in the center was pushed up and very lightly sort of fused against the rivet above it. A light touch, and it sprung back into position. I cleaned the roller and ran it again, but after a few seconds, the light in the caboose went out again.

Rinse and repeat a half-dozen times now, and I'm at a loss as to why the roller keeps getting stuck against the rivet on top of it. Any suggestions as to what's happening and what the remedy might be?

Thank you!

(PS: Might whatever is causing this be the reason for the headlight on my 682 locomotive to be out too? I haven't inspected that one at all yet. The three backup lights on the tender are working fine, however.)