Allegheny48 posted:Jayhawk500 posted:It will be a week tomorrow since I put up a post. I must say I very pleased with the results up to this point in detailing an early 1990's vintage Lionel (LTI) locomotive. I'm not finished by any stretch, I still have to put my engineer and fireman in. I have to reorder the lenses for the class lights. I have green instead of clear and I still need to put the lens on the headlight. I also added the headlight wiring conduit. The other un-noticeable thing I did was paint both boiler handrails black. These were originally stainless steel. I still need to add the numbering to the headlight.

The boiler front was definitely trying my patients. I had broke off the left class light and it was difficult at best to get it back on, lined up and square. All the while keeping the alignment for the LED hole in the bottom.

I do believe the gold eagle does bring a little of the Freedom Train in, even though I don't have any of that paint scheme on the engine at this time. (We'll see for the future.) I'm slowly finding pictures that the boiler and cab were painted blue. But with 40+ year old photography it's hard to tell between blue and black given the angles and lighting. This too will come in the future.

I still have touching up to do, paint wise. I don't have a hobby shop close by and none of the stores sells the Testors model paint. But as I said in an earlier post I headed to Portland to ride the SP Daylighter #4449 this Sunday, I'll get some then.

I think I did good.

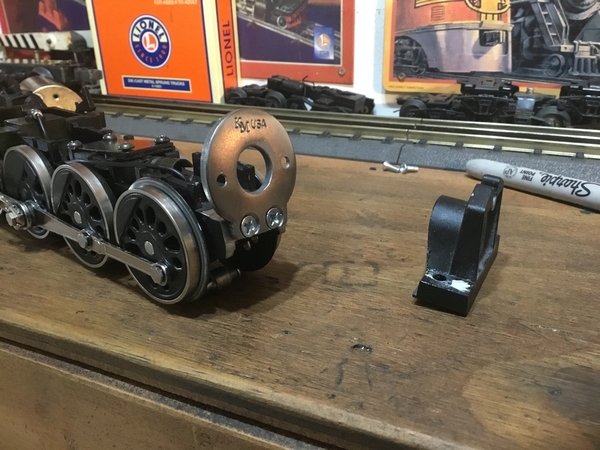

I looked to see if the front coupler on the engine would line up... If it were the correct size....It would.

I tried taking some pictures under LED bulbs on my kitchen bar, Unfortunately these lights ruined the pictures. I did get two pictures and a video. I forgot to add smoke fluid to the smoke unit and by the time I got done filming the video it was starting to burn and smell up the house. But with my luck the video didn't turn out. I'll try in the morning and use YouTube.

The next project is to get my layout set up for Christmas and run this beast. I'm sooooooo excited. I have 4 Lionel Steam Special passenger cars to put behind it.

Stay Tuned. More will come!

My Gosh!!! The engine is stunning. You've done a magnificent job recreating Ross Rowland's 2101. I also enjoyed the brief videos. Painting the handrails certainly made the engine appear more realistic. I have heard that, with early Rail Sounds, the engine's handrails often worked as an antenna. One quick question regarding the aux. tender. This may have been discussed earlier but I don't remember. Was removing its coal load and replacing it with a simulated steel plate ever considered?

Kudos to you sir. I wish I had your patience and modeling skills. Please keep the pictures and videos coming when time permits.

Thank You for the kind words.

The handrails were not antennas. This was a conventional setup engine. Yes, I did post way earlier about the metal cover for the Aux Tender. That is one of the items that I still need to do. I was going to use ABS, but since I've been working with it for the rear cab bulkhead, I think I'll just grab a piece of scrap aluminum from work and form my own. It'll be pretty straight forward.