https://news.umich.edu/3d-prin...s-faster-with-light/

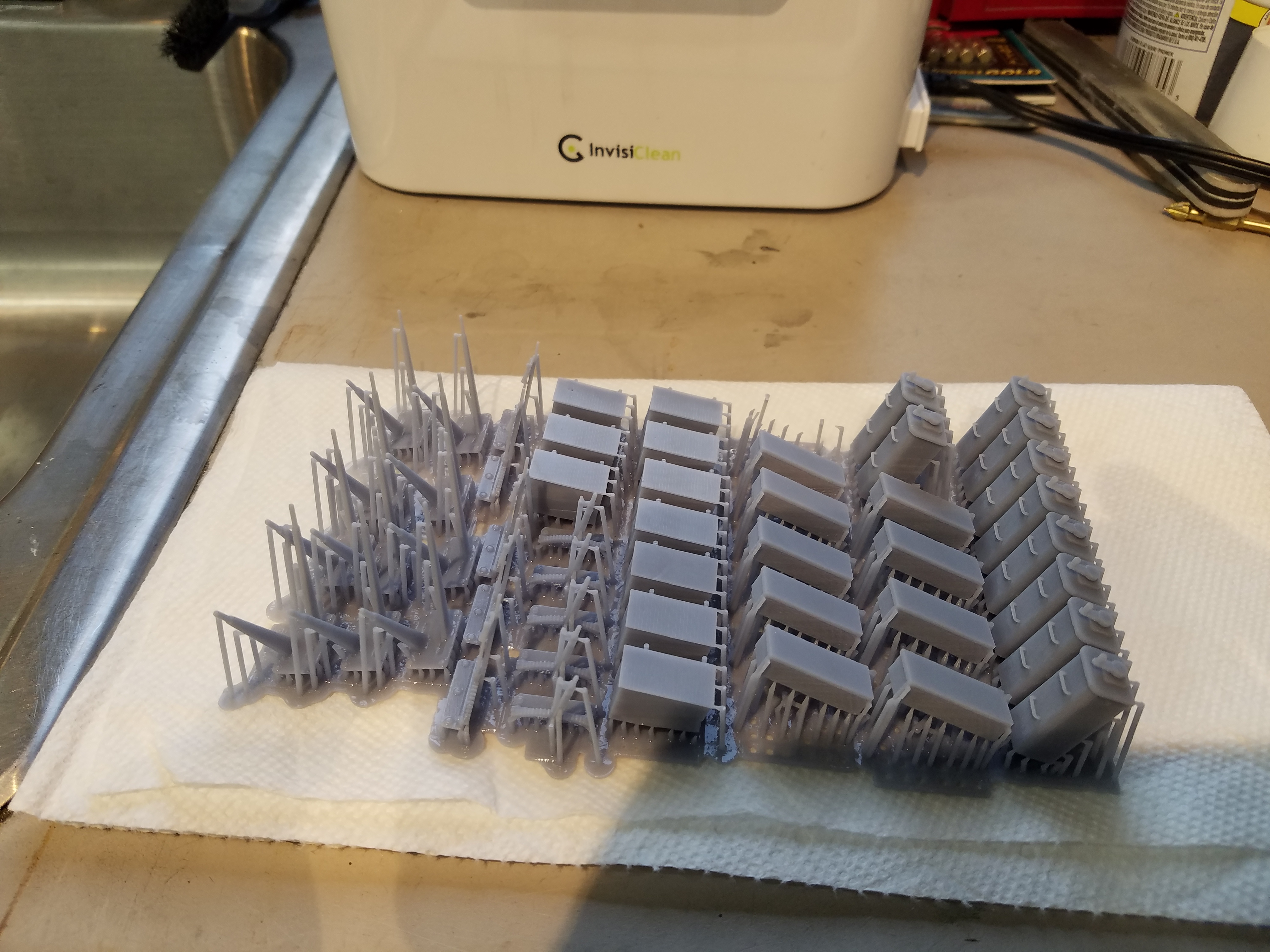

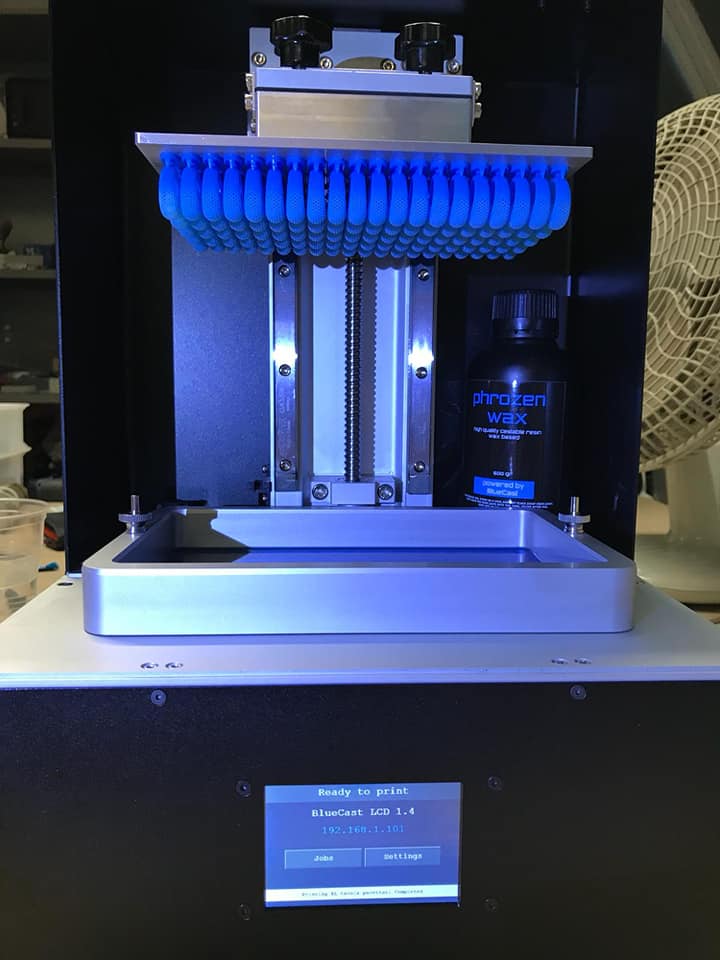

We have had discussions about 3D printing and the hobby, and this article is about a new method that may have brought us closer to where 3D printing could allow creating stuff for our trains and layouts cheaper and easier. Still a lab thing,but interesting.