I just noticed the photo captions I added did not appear in the post. The bottom picture is the insulated metal wheel.

What is intriguing about the engine that you have is that the truck sideframes are black when they should be silver.

It would be interesting to know exactly what you do have as a frame/motor chassis. Part of me wonders how if you have something of a *******ised 374/370 chassis.

Any thing is possible but that looks like a 370 chassis to me. The appearance would be consistent with the 1951 production date stamp inside the shell. I assumed a previous owner repainted the truck sideframes since they are not original to the engine. The frames have sliding pickup shoes and knuckle couplers so those frames were from an engine that had the diesel "horn" sound system.

Oops, I sent too soon. The motor and power truck could have been taken from something like a 374. Should be able to tell by which armature is in the motor.

AmFlyer posted:Oops, I sent too soon.

1. The motor and power truck could have been taken from something like a 374.

2. Should be able to tell by which armature is in the motor.

1. I'll bet that's the case here: the trucks appear to have a factory-applied finish.

2. I remember seeing something on one of the YouTube videos about there being (2) different lengths. I won't be pulling this thing apart again until the metal wheels arrive, so we'll have to wait on that bit of info. I do know it has brass worms, and I see an GP7 armature listed on eBay with nylon worms...does that help?

Mark in Oregon

Interesting project! They put the rectifier in and removed the reverse unit. so it would only run one direction off AC I think. Here is the one I got a while back, You'll probably have to clean all the contact points and remove all old hardened grease as usual. Be gentle on the little screws that attached the small bits to the cast truck blocks, they seem to be a bit delicate and the screws are self tapping....

Attachments

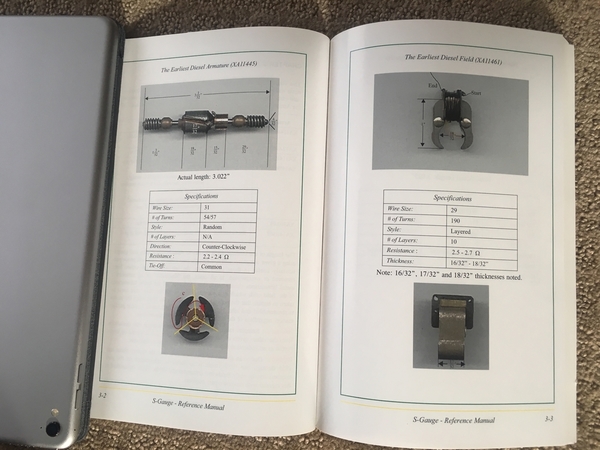

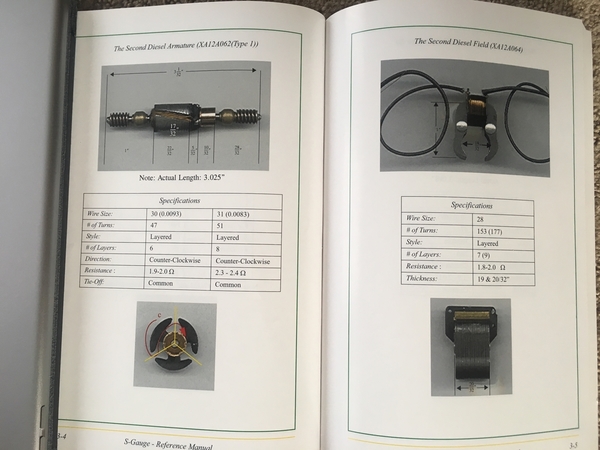

For someone who wants to closely examine the motor in a GP7 here are the armature and field configurations. A 1951 would have the earliest field. Note the only visible difference between this and the second armature is the position of the commutator slot relative to the gap in the laminations closest to the commutator. The other difference is random vs layered windings. However the fields are different. The earliest field is 17/32 while the second field is 20/32.

The third design armatures repositioned the commutator in relation to the bearing. The field was also redesigned with the square shoulders at the top. This would likely be in 5 digit engines.

Attachments

Thanks for the photos, Tom. That's quite the book! ![]()

Mark in Oregon

It is a great book by a great guy - Robert (Bob) Hannon of MD. Buy his book and give him a call if you every get really stuck on anything Flyer electrical - prewar or postwar. Does terrific work too. Best there is, especially rewinding.

Good to know: thank you, Dave. ![]()

I went ahead and bought an entire non-powered truck to serve as the source for the wheels I need: will let you all know how it goes from there...thanks again for all the advice, hints, etc.

Mark in Oregon

Update:

As it turns out , this mod wasn't nearly as difficult as I thought it would be. I don't have anything but the basic home-owners type of tools (so I wasn't sure I'd even be able to do this), but it's done.

Here are all the tools used:

The screwdriver was adequate for removing the insulated wheels. The large "Irwin" clamp was good enough to press the new insulated wheel onto the axle; I had to use the "C" clamp to press on the metal wheel. The hemostat was to ensure the axle gear stayed (more or less) centered while I pressed the new wheels on; the hammer and punch I used to knock out the axle from the replacement metal wheel.

I now have a spare set of wheels, still attached to the donor truck you see here; the caliper was for setting the wheel gauge, and the (2) loose wheels are the ones I took off the unit. I thought they were plastic, but now I think they might be metal, grooved for the "Pullmore" traction tires (?)

So there you have it; this odd example (made from several models, I'd guess), now has (8) metal wheels, no traction tires and picks up current from (2) wheels and the pick-up shoe from each rail. Much better. ![]()

As always, thanks for sticking with me on this project...

Mark in Oregon

Attachments

It looks like you now have a unique 370 that runs great. The sliding pickups are nice to have.

AmFlyer posted:It looks like you now have a unique 370 that runs great. The sliding pickups are nice to have.

Thanks: wait, not so fast!

It was running well, until about a week ago, when all of a sudden it froze up: it was getting current, but no movement. What now? ![]()

I thought at first it had something to do with the fact that I had attempted to center the axle gears, and in doing so, had over-compensated and that was causing the bind. So I took the whole thing apart again but it didn't seem like that was cause, as everything felt like it was ok.

I did notice that the "field winding" was getting hot, so I looked to the motor itself: I took it down to parts, cleaned everything, re-assembled, and nothing. I then thought about something I think one of you told me to look out for: making sure that the field is centered inside of the yoke.

Sure enough, if I tweaked the field a little, it would run again, so I knew that's where the problem was. I took a couple of flat toothpicks and shoved one into each side, between the field and yoke, to center it. Then tightened the screws (gently). That did the trick, so I left the toothpicks where they were (after snapping off the exposed ends) just to keep everything snug.

So there you go; thanks to you all, it's running again. Now I just need to get around to ordering that Dallee unit... ![]()

Mark in Oregon