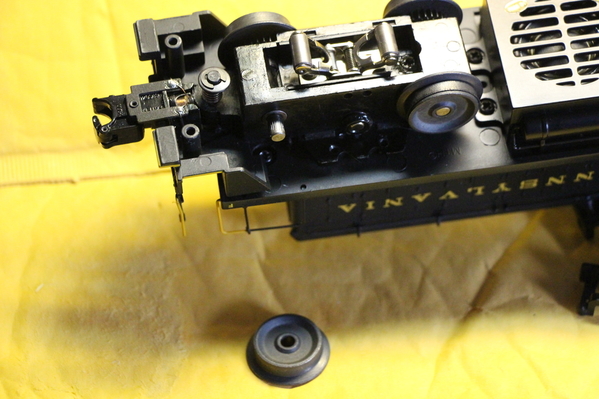

That happened to my MTH SW1 two years ago. The axle had been knurled at the factory, but apparently not good enough. I clamped needle nose vice grips on the axle and rotated them away from the engine. Rotated the axle 90 degrees and repeated. I pressed the wheel back on the axle using a C clamp. I placed dimes in the wheel recesses to keep the C clamp from marring the wheel surface and to prevent pressing the wheel too far on the axle. I don’t run the SW1 every day, but I haven’t had a problem since.

Loctite 380 BlackMax was recommended to me at the time, but since my makeshift knurling process worked, I didn’t use adhesive. If you do go with adhesive, make sure to check the wheel gauge before letting the adhesive dry.