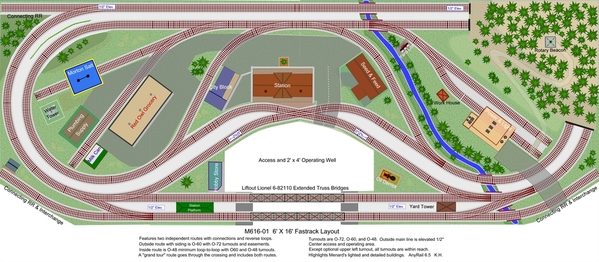

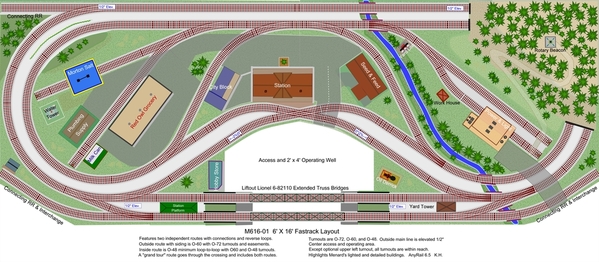

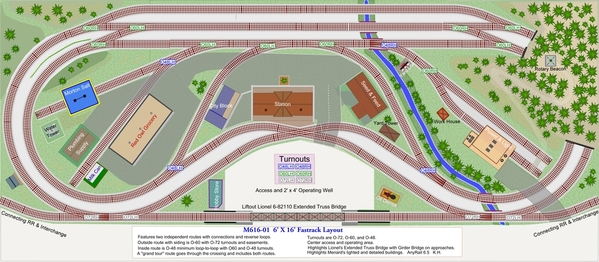

I have been playing with this plan for a basement (mine possibly) layout that emphasizes train running and routing. The plan will support 3 trains running, with a siding available for staging. The two return loops allow trains to change direction. The outer mainline is O-60 with O-72 turnouts and easements, while the inner main is O-48 minimum. For the parallel tracks, the center-rail spacing is just over 5", but varies a bit larger in places. There are three sidings that can be for expansion or give the impression of connecting railroads, or possibly used to stage cars and locomotives or interchange tracks.

The plan uses two of Lionel's Extended Truss Bridges 6-82110 that can be used as Lift-Out Bridges to give access to the center. The plan shows the lift-out bridges and the foundations that come in the package. Mike Reagan's Bridge video.

With a layout that is 6' wide, access and reach is a problem, unless the layout is an island with all-around access. This layout is intended to go up against a wall at the top, while the bottom plus one or both of the sides are accessible. The access and operating "well" in the center is a bit tight at 2'x4'.

For more visual interest, I elevated the outside mainline, siding, and interchange tracks by 1/2" all around. There is a 2% grade from the crossing up to the outside mains on either side.

If the layout can be an island with all-around access, the center access well could be replaced with a small yard or more industry tracks. Expanding the layout to O-72 minimum for the outside mainline would add 6" to the width, and a foot to the length making a 6.5' x 17' layout.

I have looked at variations on this theme, and here I was curious to see what this might look like with O-60 minimum for the outside route, handling O-54 minimum locos and cars very nicely. Comments and suggestions are most welcome! -Ken