Ok, I've got a real conundrum.

How do I extend the axles on this truck so that I can add rotating roller bearing caps to the truck side frames?

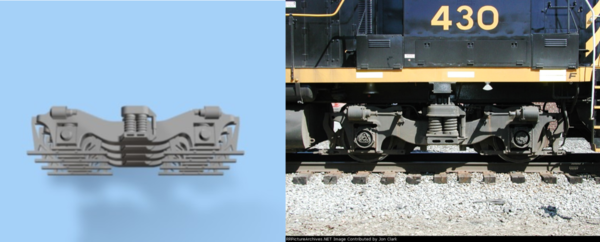

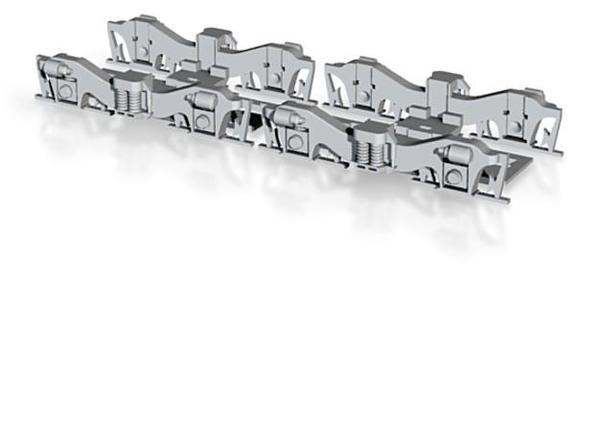

The 3D printed ALCo Hi-Ad side frames were scaled up from N or HO, and do not have roller bearing detail.

I'm already planning on removing the 3D printed springs to add real springs.

Since they were designed to be completely separated from the main frame, this should be relatively easy, and I'd insert pins like freight car trucks have

Here's the N scale design.

Any ideas?