Hello all, does anyone have or know where I could get schematics/instructions for the Indiana Harbor drive rod assembly. Any help greatly appreciated. Cheers Jim

Replies sorted oldest to newest

trainnut56 posted:Any help greatly appreciated. Cheers Jim

![]()

Yes Fred just what I needed, thank you very much. Cheers Jim

Fred, Got anything on the Casey Jones model? Does it share the Drive kit or is it able to be modified to fit? I will be powering a shell , come he....well let's hope its a small creek trestle to cross and not high water, lol.

56, I hope you don't mind this train thread robbery too much ![]()

Adriatic,

Here is a link to the (Italian) RivaRossi 0 gauge catalog: http://www.rivarossi-memory.it...ogo_Zero_1971-72.htm (click on the pages on the left to expand).

The IHB model came in 2 kits: one for the loco with plastic wheels and one to motorize the loco and this included the metal wheels. The Casey Jones model also came in 2 kits, however the model kit already included the metal wheels and the motorizing kit was simpler. Both models had the same motor but I do not think you can use the one kit to motorize the other. I might have somewhere the Casey Jones instructions, but if so they are deep in some pile. The IHB I acquired much later and the instructions were still "on top" of the pile. What information do you need?

Regards

Fred

As it turns out, maybe intstruction, but maybe nothing. I'll let you know in a few days.

I have both CJ kits on the way from Mike G. I thought it was just the shell kit, but he must have saw this thread, because he let me know the powertrain kit was included too.

I thought I was going to be kit bashing the power, and got too excited each time to ask about instructions. Ive wanted something to represent one of Casey's trains for yeats. I even contemplated bashing the Marx William Cook.

Someone had mentioned a kit without the instrictions, and I had looked at a few while waiting to see if a previous deal for it was followed through on. It wasn't, and I'd rather send my money to a great guy like him anyhow, so Im glad I waited it out. But I forgot who didn't have the instructions with the kit, lol.

Likely not a big deal; I seldom built models by using them anyhow, but they are nice if an issue rears and kicks.

Either way you'll know when I do, thank you.

I have to complete it with photos and steps in a post for the forum, just to uphold part of the bargain, (Oh, darnit ![]() ) If you folks would like a "heads up" when I post, just say so. In fact, another Rivarossi or two, all in one thread would be awsomI, if you want to add something...or keep this one going.

) If you folks would like a "heads up" when I post, just say so. In fact, another Rivarossi or two, all in one thread would be awsomI, if you want to add something...or keep this one going. ![]()

I have two CJ 4-6-0 kits....both have plastic wheels like the IHB 0-8-0. The 4-4-0 kits DID include metal wheels but not the motor. Cool kits....wish all the parts were still made....they were easy to convert to 3r.

ADRIATIC,

I did see the thread, Just so you know the Casey Jones Kit has 3 sheet of instructions, and there are instructions for the motorizing kit in there somewhere also! I hope you enjoy the build.

Interesting link to the 1972 catalog. I wonder if those Santa Fe coaches were made? I have not seen them in any train shows here in the northeast.

I got it, 4 sheets of instructions and a motor kit parts list. English,German, French and Italian versions. I'll follow up more after I download updates. I loose text after each program finishes.

I have two of those kits that are new. I also have a drive/power kit and they will go for sale after York.

Cool I am glad you got it! ENJOY!

I'd like to find a set of these two 0-8-0 kits of my own, someday.

You can count on it Mike! Thanks again,& again,& again.

Oh man...Your killing me Marty. I already double head my Generals; this could get interesting as I planned on running them at the same time as an "era" thing.

Do these flanges stand a chance on Super O, or will I be hand laying some 2rail? Railing an axle, they seem under gauge on tube and SO, lots of wiggle room.(Euro O is slightly different from American O if I recall. I forgotten by how much, but I know it differs, or used to anyhow.

This has nothing to do with Mike, he packs as expected:

An envelope failed en route and a rod spacer found a crack and fell out. No big deal. Finding a washer/ spacer should do the trick, but the original spacer is stainless. I'm going to raid a guy's HO junk box and hope I find something. It ironically was the largest of them that found a gap in the well sealed shipping box. But still, it's only 4.5mm od X 2.55 mm i.d. X .46mm thick (.177 X .1 X .018 inches -ish)

A few others that are way more critical got stuck to the tape ![]() right near the dented corner of the shipper, which had caused a very small gap. I dissected the box; no luck

right near the dented corner of the shipper, which had caused a very small gap. I dissected the box; no luck ![]()

I found it! And an extra thin spacer too unless I missed something in the instructions. It was between the front door and where I opened the box up. The dog, "Puppy" (too interested in anything I do) tried licking it up while I grabbed my parts box, but had bad aim and missed it, so I'm set.

Ok, Trainnut is going to graciously host this Rivarossi party while I build.

I started a trial assembly, but decided to work on the tender first to get used to working with this plastic. It's a hard shiney black styrene similar in look to a brand new post war tender. There is little flash, even at the flow holes. I'm tempted to not paint it, but we'll see how it looks, and how I feel about things later. The fit is pretty good. Cornections for the pieces have a series of 2 small teats here and there at the corners that rest crossed together and once filled with glued should make for good strong anchor points. I'll use up some ancient Kmart brand tube of styrene glue from the 70s. I saved a few tubes for its quality, but this should fittingly finish off the last tube.

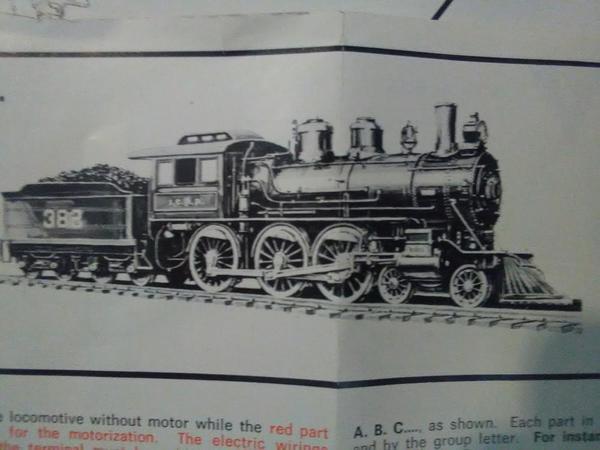

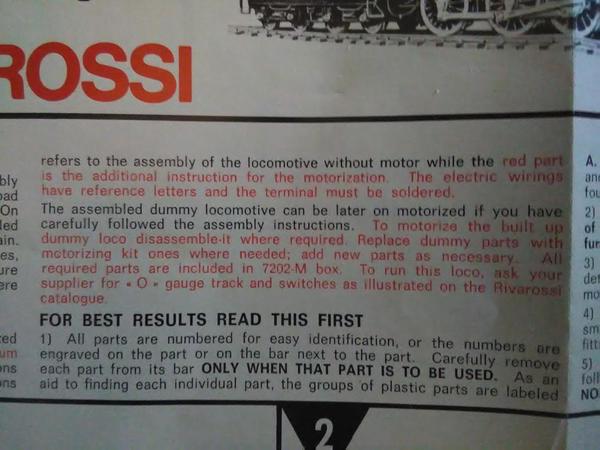

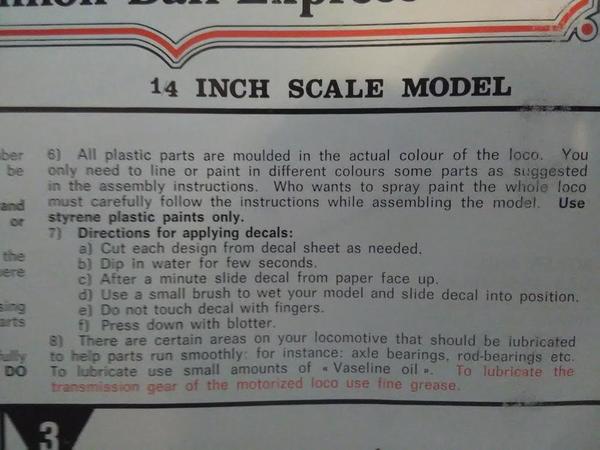

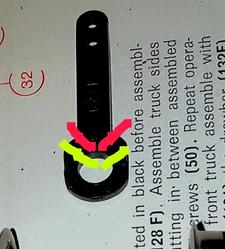

Here is the instructions header and parts list for the motor kit before I get rolling. Good advice is listed. These are pretty good instructions from what I see off fhand. Red in diagrams are from the electric kit, and black is the model kit. I'd label the bags with a sharpie and not mix things as placement in bags, and count on screws is a puzzle that should sort itself as you go. EG. #32 2 are nearly the same screw. But some are printed red and some black, and the correct screw number can be found in both bags, and each bag holds a different. Amount, so it's a counting juggle on totals, and totals let bag to id them. (I have extras and am going to cheat)) Had I realized this, I would have created a key list, but too late.

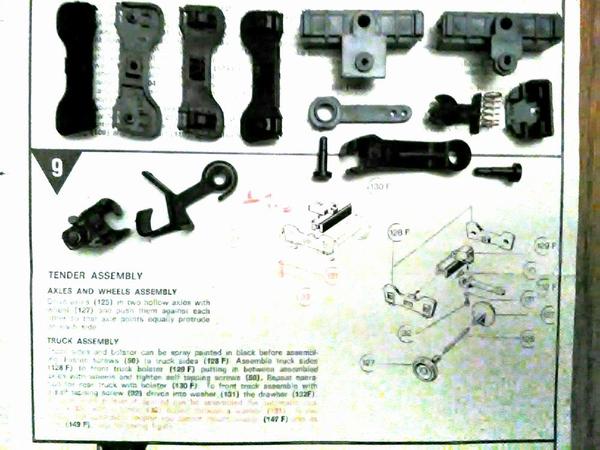

Step 9- the trucks

This is where I began, and right away ran into an issue, so I'm glad that I did start here, it gives me time to work on it before the loco is done.IIl post the text next post, this is a late addition to a long post.

Two of the tender axel's were lost in shipping; part of that envelope splitting open. It shouldn't be too hard to fab them if I cant find more

The tips step has a 1.13mm(.045") dia. shaft, and each step is about 3.85mm(.15")long. The thick portion 1.95mm(.075) dia. for 37.95mm(1.48) step to step, with a total length at 45.8mm(1.8") tip to tip. Any ideas let me know. I'll use the two I do have have, one on each truck for now.

One wheel set finger pressed together, but the other needed a vice to press one of the wheels,, but barely. The wheels have cooling fins and do look great imo.

The parts. There is a lionel knuckle for comparison by that GIGANTIC copy of the old school HO type the kit includes, and a toy coupler I'll use till I locate a plastic dummy lobster claw or a Kd version that works with lobster claws. There is a scale coupler and gear box that body mounts by snapping in place that is included too. It looks easy to swap systems at a whim; nice

The pins are for ballast plates in the tender

That HO-ish coupler could be heated/bent/trimmed to work in a pinch, I bet.

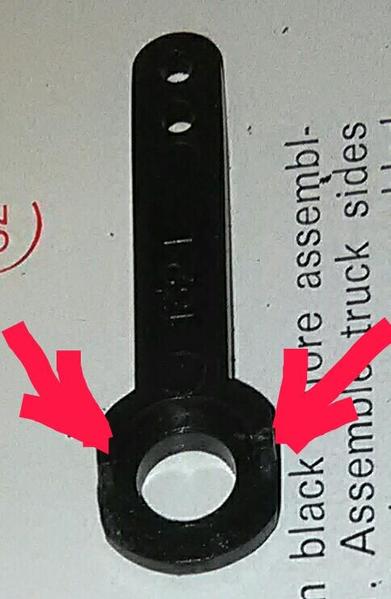

Not much side to side swing on the stock parts. There is a cast ridge that locks the hO ish one in place. File that off and it would center by spring action. The draw bar has notches that severely limit is swing. It looks like it swings enough for 031 curves, but I will take some of the limiting plastic off with a dremel just in case it rides tubular ok, it will be set for 0-27 too.

(Edit: no trimming needed for the tender to take an 0-27 turn behind a General, but this AHM 4-6-0 engine is 0-36 minimum )

One truck had some flash at the arrow to remove from the pocket. But others were perfect. The trucks s screw together, no glue needed . Its side frame screws being correct is a bit of a puzzle having to do with screw counts supplied in each bag, from each kit. I'm ignoring that puzzle and using the longest with pointed ends because of a two thread advantage over the self tappers, which I ran in first for the cutting action, then swapped in the longer. If I feel the need for longer ones again later for the intended use, I have some longer ones I'm sure.

To be continued........

Attachments

Adriatic

Thanks for sharing, but only 1 of your photos is showing in that last post

Bob